| Tightening torques | |

| High pressure fuel pump mounting bolts | 23 Nm |

| Nut for fastening the injection pump pulley | 70 Nm |

| Nuts of fastening of a trench and a tube of an oil dipstick on a fuel distribution rail | 21 Nm |

Important note.

- Before carrying out any work on the injection system, check with a scan tool: that the rail pressure has been relieved, that the fuel temperature is not high.

- When carrying out any work, the instructions for cleanliness and safety given in this document must be observed.

- It is strictly forbidden to carry out any work on the injection system while the engine is running. Attention

- To prevent corrosion or damage, provide protection to areas where fuel can be hazardous.

Note: Never turn the engine crankshaft in the opposite direction to the direction of rotation.

Removing

Place the car on a two post lift.

Disconnect the battery.

Remove the engine top cover.

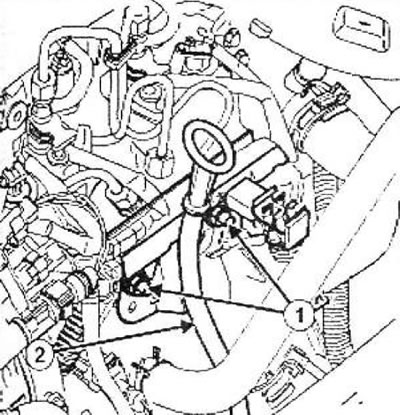

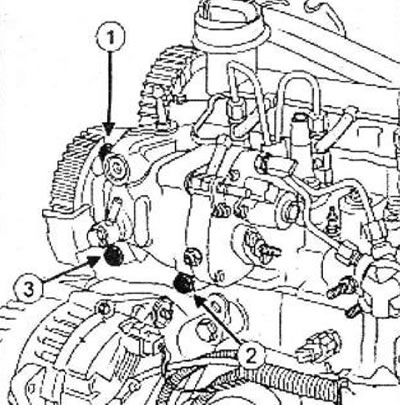

Remove the oil dipstick and filler nuts (1).

Move aside the oil dipstick tube (2).

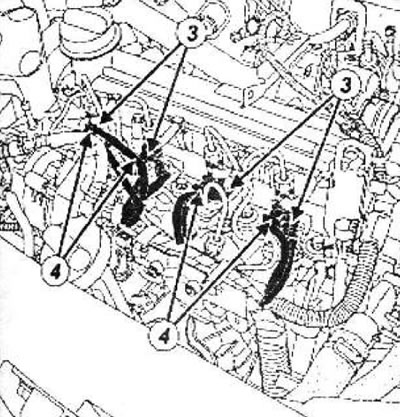

Disconnect:

- glow plugs (3),

- nozzles (4),

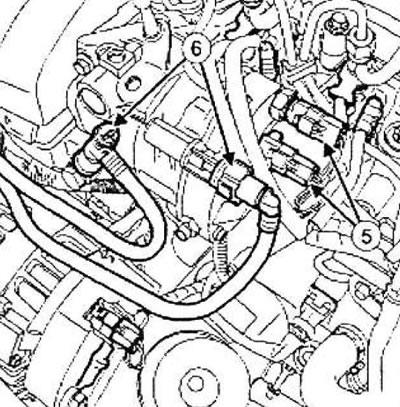

- injection pump connectors (5).

Clean the fuel supply and return lines.

Disconnect the fuel supply and return lines (6).

Close the holes with plugs.

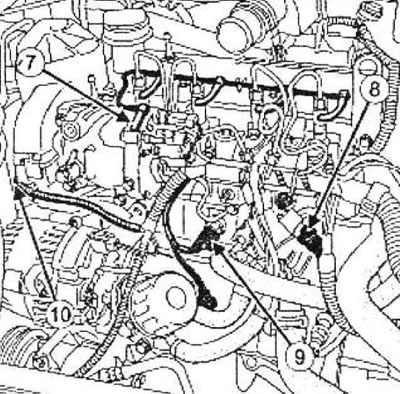

Disconnect:

- drain fuel line (7), connecting the injectors to the injection pump,

- rail pressure sensor (8),

- block of wires from the accelerometric sensor (9),

- camshaft position sensor (10).

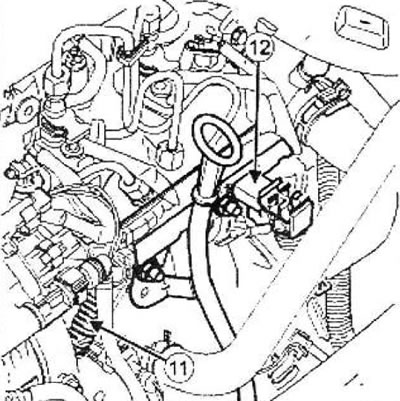

Loosen engine wiring (11) and take her aside.

Remove the chute (12), located on the fuel rail.

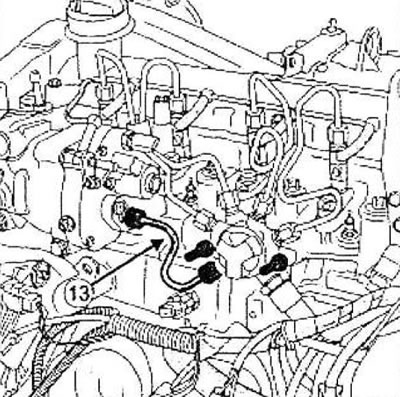

Remove the high pressure fuel line (13) between the fuel rail and injection pump.

Install spark plug plugs in all holes in the injection system.

Remove:

- right pendulum suspension support,

- camshaft position sensor.

- upper timing cover,

- lower timing cover,

- pendulum support of the cylinder head.

Set the piston of the 1st cylinder of the engine to TDC.

Install the tools for fixing the injection pump sprocket (14).

If necessary, turn the crankshaft a little so that the lock fits on the teeth of the injection pump pulley.

Loosen the nut (15) fixing the toothed pulley of the injection pump. holding the 32mm pulley with a flat wrench.

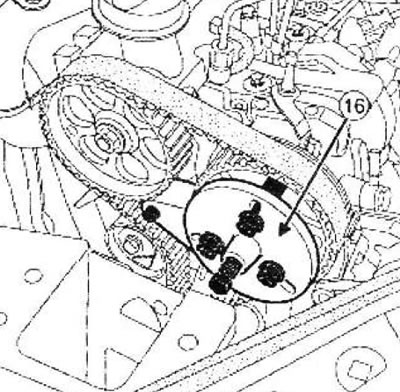

Install fixture (16) complete with fixture.

Attention! Make sure that the device pusher is installed strictly along the axis and rests against the injection pump roller.

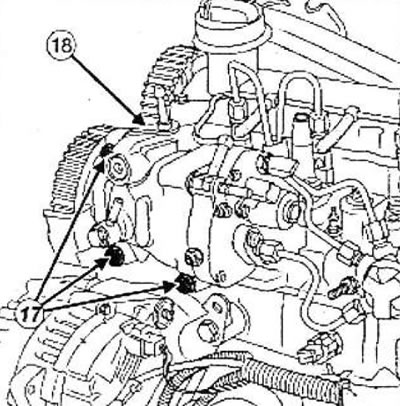

Remove: mounting bolts (17) injection pump, bracket (18) engine cover mounts.

Wrap the pusher of the device until the injection pump housing is separated from the seat.

Remove:

- injection pump,

- diagnostic device.

Installation

Check for the presence of the locating pin on the injection pump shaft.

Install the injection pump on the cylinder head by inserting it into the injection pump pulley.

Note: Make sure that the injection pump shaft is in the correct position relative to the pulley.

Install the engine cover bracket.

Wrap, without tightening, bolts of fastening of TNVD.

Torque tighten the injection pump mounting bolts (23 Nm) in the specified sequence.

Torque tighten the injection pump pulley nut (70 Nm), while holding the injection pump pulley with a 32 mm wrench.

Note: Check the condition and correct installation of the timing belt.

Remove the tool from the cylinder head.

Remove plugs.

Install the high pressure fuel line between the injection pump and the injection rail.

Install:

- pendulum support from the cylinder head,

- lower timing cover,

- top timing cover.

- camshaft position sensor,

- right pendulum suspension support,

- neck located on the fuel distribution rail.

Attach the engine wiring harness to the neck.

Attach:

- camshaft position sensor,

- block of wires from the accelerometric sensor,

- rail pressure sensor,

- drain fuel line connecting the injectors to the injection pump,

- supply and drain fuel lines to high pressure fuel pump,

- connectors for injection pump,

- injectors,

- glow plugs.

Install the oil dipstick tube.

Torque tighten the nuts securing the chute and dipstick tube to the fuel rail (21 Nm).

Connect the battery.

Start the engine.

Check for fuel leakage.

Install the engine top cover.