| Tightening torques | |

| Hollow bolt for fastening the oil supply line to the turbocharger | Togh bolt 18 Nm or hex head bolt 14 Nm |

| Nut of fastening of the inlet oil pipeline of the turbocharger to the head of the block of cylinders | Collared nut 35 Nm or nut without collar 23 Nm |

| Bolts for fastening the oil outlet pipe to the turbocharger | 12 Nm |

Attention!

- Make sure that no foreign objects get into the turbine or compressor during installation.

- Check that the turbocharger oil outlet line is not partially or completely blocked by carbon deposits. Make sure there is no fuel leakage. Check for leaks, if there are, replace the part.

- A turbocharger failure leads to the ingress of metal particles into the intake tract and into the lubrication system.

- Failure to follow the instructions below will result in repeated failure of the turbocharger.

Note: This procedure describes the removal and installation of the turbocharger oil return and return lines.

Removing

Disconnect the battery.

Remove:

- engine top cover, air filter housing,

- protection of the pallet crankcase of the engine, catalytic converter.

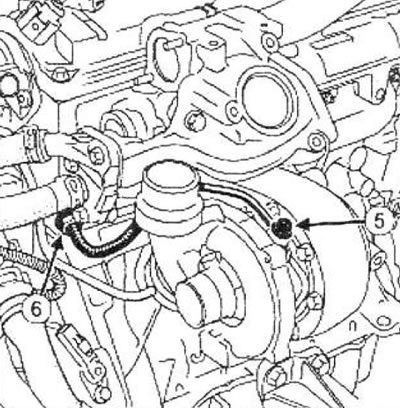

loosen the nut (6) fastening the turbocharger oil supply line fastening to the cylinder head using a tool.

Remove:

- hollow bolt for fastening the oil supply line from the turbocharger,

- turbocharger oil supply line.

Wipe up any oil spills.

Installation

Parts that must be replaced:

- Turbocharger oil supply line.

- Turbocharger oil line gasket.

- Turbocharger oil supply line bolt.

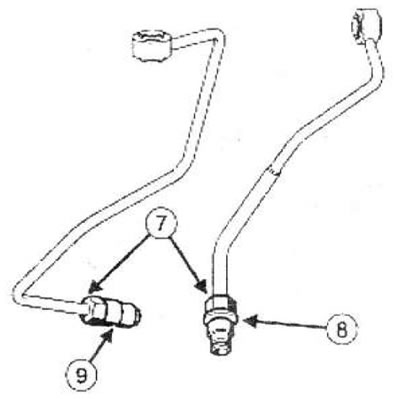

Note: Both of these turbocharger oil lines can be installed on the same engine. Tips (7) fastenings of oil lines to the cylinder head are tightened by different moments:

- if the tip has a shoulder (8), there is no need to apply a high-strength locking compound to the ferrule threads.

- if the tip does not have a shoulder (9), a high-strength locking compound must be applied to the tip threads.

Install a new turbocharger oil supply line.

Screw, without tightening, the nut securing the new turbocharger oil supply line to the cylinder head.

Install a new turbocharger oil feed pipe banjo bolt to the turbocharger.

Torque tighten:

- hollow bolt for fastening the oil supply line to the turbocharger (Torx bolt 18 Nm or hex head bolt 14 Nm),

- nut for attaching the turbocharger oil supply line to the cylinder head (nut with collar 35 Nm or nut without collar 23 Nm) with a tool or tool.

Install:

- catalytic Converter,

- protective screen.

- air filter housing,

- engine top cover.

Connect the battery.

Disconnect the high pressure pump fuel regulator connector and the connectors of each injector to avoid starting the engine.

Connect a compression tester for diesel engines to an independent starter.

Operate the starter for a few seconds until the oil pressure warning light on the instrument panel goes out.

Switch off the ignition.

Disconnect the independent starter.

Connect the high pressure pump fuel regulator connector and the connectors of each injector.

Start the engine.

Leave it to idle, then rev it up a few times with no load.

Switch off the ignition.

Check: operation of the turbocharger, check that there are no oil leaks at the turbocharger.

Check with a scan tool that there are no stored faults; process them if necessary and delete them from memory.