Share with friends:

Brake system of the car Renault Espace 1 and 2

Brake Specifications

General characteristics Type of construction - Diagonal-split dual-circuit brake system with brake booster and load-dependent brake pressure regulator Front wheel brakes - Disc, self-adjusting Rear wheel brakes - drum...

General characteristics Type of construction - Diagonal-split dual-circuit brake system with brake booster and load-dependent brake pressure regulator Front wheel brakes - Disc, self-adjusting Rear wheel brakes - drum...

General description of the braking system

Despite the fact that all models have a dual-circuit brake system, the brake systems of different models still differ. See specifications for details. The piston of the dual-circuit master cylinder actuates the right...

Despite the fact that all models have a dual-circuit brake system, the brake systems of different models still differ. See specifications for details. The piston of the dual-circuit master cylinder actuates the right...

Master brake cylinder — removal and installation

1. All models have different brake master cylinders. Most vehicles have an O-ring installed between the brake booster and the master cylinder, which should always be changed during disassembly. 2. Thoroughly clean the...

1. All models have different brake master cylinders. Most vehicles have an O-ring installed between the brake booster and the master cylinder, which should always be changed during disassembly. 2. Thoroughly clean the...

Brake Master Cylinder — Disassembly

The master brake cylinder cannot be disassembled, therefore, in case of damage, it must be replaced. The cylinder bore on all 4-cylinder models is the same, only the cylinder on V6 models has a larger diameter.

The master brake cylinder cannot be disassembled, therefore, in case of damage, it must be replaced. The cylinder bore on all 4-cylinder models is the same, only the cylinder on V6 models has a larger diameter.

Replacing the pads in the front disc brakes

1. It is time to replace the brake pads if the total thickness of the pad, including the metal backing, is 6.0 mm. This value can be measured with a ruler (see illustration), without removing pads. Use a repair kit to...

1. It is time to replace the brake pads if the total thickness of the pad, including the metal backing, is 6.0 mm. This value can be measured with a ruler (see illustration), without removing pads. Use a repair kit to...

Front disc brake caliper — removal and installation

1. When removing and installing the disc brake caliper, follow the instructions previous chapter . After that, the caliper can be removed. Two bolts attach the entire caliper to the steering knuckle (see illustration)....

1. When removing and installing the disc brake caliper, follow the instructions previous chapter . After that, the caliper can be removed. Two bolts attach the entire caliper to the steering knuckle (see illustration)....

Front disc brake caliper — disassembly

1. Remove the fastening ring and carefully remove the dust cover with a screwdriver. 2. Place a block of wood between the piston and brake caliper and blow out the piston with compressed air (see illustration). 7.2...

1. Remove the fastening ring and carefully remove the dust cover with a screwdriver. 2. Place a block of wood between the piston and brake caliper and blow out the piston with compressed air (see illustration). 7.2...

Brake discs — inspection, removal and installation

1. Brake discs must not be ground and must be replaced if worn. Brake disc wear should not exceed 0.5 mm on both sides of the disc. Check the brake disc for runout. To do this, fix the dial micrometer in such a way that...

1. Brake discs must not be ground and must be replaced if worn. Brake disc wear should not exceed 0.5 mm on both sides of the disc. Check the brake disc for runout. To do this, fix the dial micrometer in such a way that...

Rear wheel brake drums — removal and installation

1. Brake drums are removed and installed as described in chapter 17 when replacing rear wheel bearings. 2. Beforehand remove the device for installation of a normal backlash between a brake drum and pads. To do this,...

1. Brake drums are removed and installed as described in chapter 17 when replacing rear wheel bearings. 2. Beforehand remove the device for installation of a normal backlash between a brake drum and pads. To do this,...

Rear brake pads — removal

1. After disassembling the brake drum, sketch the location of the individual components. This is especially important for return springs. 2. Jack up the rear of the vehicle and place it on axle stands. 3. Remove the...

1. After disassembling the brake drum, sketch the location of the individual components. This is especially important for return springs. 2. Jack up the rear of the vehicle and place it on axle stands. 3. Remove the...

Rear brake pads — installation

1. Move the setting lever of the leading brake shoe, and the lever of the hand brake of the driven brake shoe to new brake shoes, if they are changed: 2. Move the setting lever on the drive shoes as follows: A) Remove...

1. Move the setting lever of the leading brake shoe, and the lever of the hand brake of the driven brake shoe to new brake shoes, if they are changed: 2. Move the setting lever on the drive shoes as follows: A) Remove...

Wheel Brake Cylinder — Disassembly

1. The brake cylinder can be removed after removing the brake pads as described above. The wheel cylinder cannot be repaired. To remove, unscrew the brake actuator pipeline, unscrew the two bolts and remove the...

1. The brake cylinder can be removed after removing the brake pads as described above. The wheel cylinder cannot be repaired. To remove, unscrew the brake actuator pipeline, unscrew the two bolts and remove the...

Replacing rear disc brake pads

1. If the total thickness of the pads, including the metal disc, is 6.0mm, the brake pads must be replaced. When removing, proceed as follows: 2. Remove the wheels, jack up the rear of the vehicle and place it on axle...

1. If the total thickness of the pads, including the metal disc, is 6.0mm, the brake pads must be replaced. When removing, proceed as follows: 2. Remove the wheels, jack up the rear of the vehicle and place it on axle...

Rear disc brake caliper — removal and installation

1. Remove the brake pads as described above. 2. Disconnect the caliper drive line. 3. Disconnect the brake cable. 4. Loosen and remove both screws (see illustration). 14.4 Bolts (A) caliper attachment to rear axle 5....

1. Remove the brake pads as described above. 2. Disconnect the caliper drive line. 3. Disconnect the brake cable. 4. Loosen and remove both screws (see illustration). 14.4 Bolts (A) caliper attachment to rear axle 5....

Rear disc brake caliper — repair

1. Clamp the caliper with pads in a vise. 2. Remove the dust ring. 3. Rotate the piston until it turns freely ( see illustration 13.7 ). 4. Place a piece of wood between the piston and caliper and blow out the piston...

1. Clamp the caliper with pads in a vise. 2. Remove the dust ring. 3. Rotate the piston until it turns freely ( see illustration 13.7 ). 4. Place a piece of wood between the piston and caliper and blow out the piston...

Brake discs

Brake discs cannot be ground and must be replaced if excessive wear occurs. Brake disc wear cannot exceed 0.5 mm on both sides. Check the brake disc with a dial micrometer for runout. To do this, fix the micrometer with...

Brake discs cannot be ground and must be replaced if excessive wear occurs. Brake disc wear cannot exceed 0.5 mm on both sides. Check the brake disc with a dial micrometer for runout. To do this, fix the micrometer with...

Parking brake — adjustment

Drum brakes If the brake pads are replaced or new drive cables are installed, the parking brake only needs to be adjusted. The parking brake cables must be installed in a certain way to allow automatic adjustment. In...

Drum brakes If the brake pads are replaced or new drive cables are installed, the parking brake only needs to be adjusted. The parking brake cables must be installed in a certain way to allow automatic adjustment. In...

Bleeding the brake system

1. If for any reason the connections of the brake pipes, hoses or other components of the brake system are broken, it is necessary to bleed the system from air. 2. Before pumping, remove dirt from the pumping fittings...

1. If for any reason the connections of the brake pipes, hoses or other components of the brake system are broken, it is necessary to bleed the system from air. 2. Before pumping, remove dirt from the pumping fittings...

Brake drive booster

1. Do not repair the brake booster yourself, as this requires special tools. The failure of the booster does not entail a loss of braking, only the application of more force on the brake pedal is required to have the...

1. Do not repair the brake booster yourself, as this requires special tools. The failure of the booster does not entail a loss of braking, only the application of more force on the brake pedal is required to have the...

Vacuum Pump — Diesel

Vacuum pump (see illustration) serves to create a reduced pressure for the brake booster on models with a turbodiesel engine. Removing and installing the pump is not difficult. First you need to disconnect the hose...

Vacuum pump (see illustration) serves to create a reduced pressure for the brake booster on models with a turbodiesel engine. Removing and installing the pump is not difficult. First you need to disconnect the hose...

Anti-lock braking system (ABS)

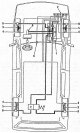

Second generation vehicles may be equipped with an anti-lock braking system. The system does not need frequent repairs. Diagram of the brake system with ABS and the location of its individual components are shown in...

Second generation vehicles may be equipped with an anti-lock braking system. The system does not need frequent repairs. Diagram of the brake system with ABS and the location of its individual components are shown in...

Speed sensors and front wheel rims

The speed sensors are wired directly to the electronic module. The process of removing and installing the sensors is relatively simple, since after disconnecting the cable, all that remains is to remove them. The sensor...

The speed sensors are wired directly to the electronic module. The process of removing and installing the sensors is relatively simple, since after disconnecting the cable, all that remains is to remove them. The sensor...

Brake hoses

Brake hoses on early Espace models are structurally different as they do not use o-rings. The tightness of the connection is created by the cone-shaped end of the hose installed in the corresponding opening of the...

Brake hoses on early Espace models are structurally different as they do not use o-rings. The tightness of the connection is created by the cone-shaped end of the hose installed in the corresponding opening of the...

This section is available on: russian, bulgarian, belarusian, ukrainian, serbian, croatian, romanian, polish, slovak, hungarian

Other sections on other Renault models

➽ Chassis, running gear: Brake system Renault Fluence 1 (2009-2020, petrol)

➽ Chassis, running gear: Brake system Renault Kangoo 1 (1997-2007)

➽ Chassis, running gear: Brake system Renault Laguna 2 (2001-2007)

➽ Chassis, running gear: Brake system Renault Logan 2 (2012-2020)

➽ Chassis, running gear: Brake system Renault Megane 1 (1995-2002)

➽ Chassis, running gear: Brake system Renault Sandero 1 (2007-2012)

➽ Chassis, running gear: Brake system Renault Scenic 1 (1996-2003)

➽ Chassis, running gear: Brake system Renault Symbol 2 (2008-2013, petrol)

Link to this section in different formats

TEXTHTMLBB Code

- General information

- Maintenance

- Power unit

- Engine repair

- Exhaust system

- Cooling system

- Supply system

- Single-point injection

- Multi-point injection

- Diesel injection system

- Transmission

- Clutch

- Car gearbox

- Chassis, running gear

- Car suspension

- Steering

- Brake system

- Wheels and tires

- Body and interior

- Exterior (external elements)

- Interior (internal elements)

- Heating and ventilation

- Electrical equipment

- Equipment and devices

- Headlights and lighting

- Ignition system

- Power devices

- Electrical circuits

- General information

- Introduction to the guide

- Troubleshooting

- Power unit

- Engine repair

- Cooling system

- Carburetor fuel system

- Injection fuel system

- Diesel fuel system

- Ignition system

- Transmission

- Clutch

- Car gearbox

- Drive shafts

- Chassis, running gear

- Brake system

- Steering

- Front suspension

- Rear suspension

- Body and interior

- Exterior (external elements)

- Interior (internal elements)

- Doors, locks and windows

- Electrical equipment

- Equipment and devices

- Electrical circuits

- General information

- Introduction to the manual

- User manual

- Power unit

- Petrol engines F3R

- Petrol engines Z7X

- Diesel engines G8T

- Diesel engines G9T

- Transmission

- Clutch

- Mechanical gearbox

- Automatic gearbox

- Drive shafts

- Chassis, running gear

- Steering

- Front suspension

- Rear suspension

- Brake system

- Body and interior

- Exterior (external elements)

- Interior (internal elements)

- Doors, locks and windows

- Heating and ventilation

- Electrical equipment

- Equipment and instruments

- Power devices

- Electrical circuits

RenaultBook.ru © 2018–2024 | Mobile version | News and articles | Sitemap: EN BG BY UA RS HR RO PL SK HU | Administration | Site search | Bookmark

Duster 1 (2009-2017) | Fluence 1 (2009-2020, petrol) | Kangoo 1 (1997-2007) | Laguna 2 (2001-2007) | Logan 1 (2004-2012, petrol) | Logan 2 (2012-2020) | Megane 1 (1995-2002) | Megan 2 (2002-2009, petrol) | Sandero 1 (2007-2012) | Scenic 1 (1996-2003) | Symbol 1 (1999-2008, petrol) | Symbol 2 (2008-2013, petrol) | Renault 19 (1988-1996) | Espace I and II (1984-1996) | Espace III (1996-2002) |