The injection system and the ignition system are controlled by an electronic module. -

Ignition timing is determined by a sensor that is integrated between the second and third cylinders under the intake manifold on a 4-cylinder engine, or in the cylinder block near the oil filter on a V6 engine. The sensor accurately receives «sound» or «knock» fuel and transmits this pulse for processing to the control unit.

The electronic control device is installed in the cabin in the tunnel of the center console (models J116/J117) or on the right fender in the engine compartment for other models.

The lambda sensor, which detects the oxygen content in the exhaust gases, is installed in the front of the exhaust pipe on models with a 4-cylinder engine, or directly in the catalyst on models with a V6 engine.

The system also includes an idle speed control solenoid valve. The valve is installed in the bypass channel.

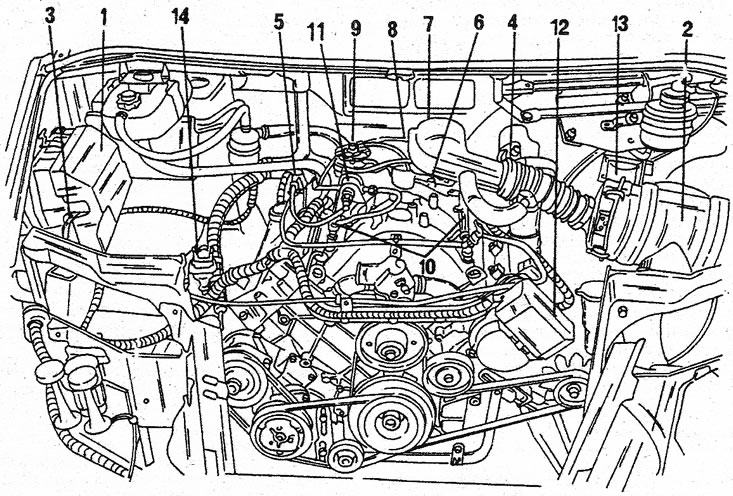

The injection system consists of three main parts: the power supply system, the electronic module and the sensors that send signals to it, and the power supply system. Illustration 9.1 shows the engine compartment of a car with a V6 engine.

9.1 Location of individual parts in the engine compartment of a vehicle with a V6 engine 1. Electronic module 2. Air filter 3. MAP sensor 4. Idle speed control valve 5. Fuel lines 6. Throttle body 7. Throttle potentiometer 8. Intake air temperature sensor 9. Throttle cable drum 10. Fuel distribution line. 11 Fuel pressure regulator 12. Ignition distributor 13. Ignition module 14. Central plug socket for connecting a diagnostic stand

The brain of the system is a single-chip processor, which also controls the ignition system.

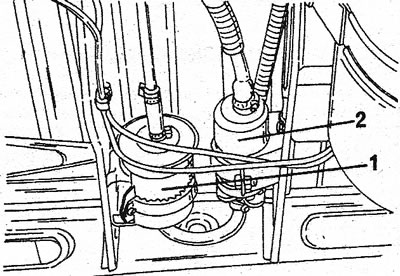

Fuel is supplied by an electric fuel pump, which is mounted on the right longitudinal beam of the body in front of the fuel tank and is closed with a lid. On earlier models, the pump is installed next to the fuel filter, as shown in illustration 9.2.

9.2 Fuel filter position (1) and fuel pump (2) on early models (J116 and J117)

Four or six electromagnetic nozzles operate under the control of electrical signals (12 Volt) module.

The fuel injection system operates on the basis of signals from various sensors and control factors, some of which are mentioned below. The full load on the engine is determined by the position of the throttle valve at a certain opening angle. The idle position is set as soon as the throttle lever hits the stop pin and the idle switch is actuated. The Solex throttle body has a different diameter depending on the type of engine. The thermal switch responds to changes in engine temperature. The switch is installed in the cooling system and informs the module of the coolant temperature in all operating conditions. The information enters the computer, where it is processed in order to make the necessary adjustments. The intake air temperature is measured to supply the engine with the required amount of air, i.e. air is dosed according to the temperature.

The fuel supply process is complex, i. the computer has a microprocessor, a program and a data bank, as well as an analog-to-digital converter. The computer determines the injection time based on the throttle position and engine speed, which are transmitted to it by electrical signals from the corresponding sensors. The received signals of various throttle positions and engine speeds are recorded and accumulated in a special memory. Whenever both of these criteria are in the required ratio, the injection timing is determined, which is related to the quality of the air-fuel mixture in the cylinders, regardless of the engine load.

How is the air-fuel mixture adjusted? The lambda sensor sends an electrical signal to the module, and the module changes the composition of the air-fuel mixture and at the same time extends or shortens the injection time. This Lambda sensor allows precise dosing of fuel, thereby helping to establish the CO content in the working mixture within the prescribed limits.

The idling speed is automatically reduced or increased as required by the operating conditions. The idle speed control valve sets the throttle according to the engine speed for any given moment and the programmed relative value. This relative idle speed is detected by various sensors and determines the throttle position angle as required. The idle system does not require any adjustments.