Attention. The steering gear and power steering pump cannot be repaired.

Removal

- Disconnect the cable from the negative terminal of the battery.

- Set the car wheels to move straight ahead.

- Raise the car.

- Remove the wheels and left wheel liner.

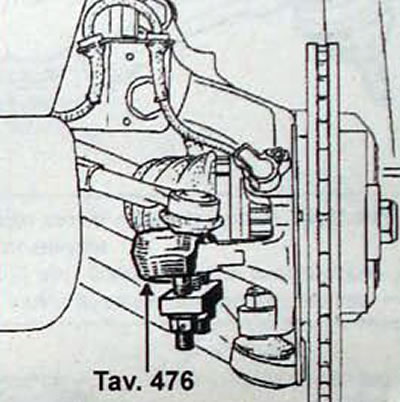

- Puller T. Av. 476 disconnect the tie rod end ball joint from the steering knuckle.

Pic. 9.9. Using the Tav puller. 476 to disconnect the tie rod end from the steering knuckle

- Unscrew the nuts securing the lower ball joints of the stabilizer bar struts.

- Unscrew the nuts securing the ball joint pins of the lower arms of the front suspension.

- On vehicles with Z and G engines, remove the exhaust downpipes from the exhaust manifold to the catalytic converter. Unscrew the nut and remove the torque rod mounting bolt.

- On cars with F engines, move the cover, unscrew the bolt securing the drive rod end to the gear selector lever and remove the gear shift rod.

- On vehicles with all engines, unscrew the nut and bolt connecting the steering shaft universal joint fork.

- Use a special device to block the steering wheel to prevent the slip ring from changing position.

- Unscrew the two bolts securing the brake hose holders, the wires of the brake pad wear warning lamp and the ABS sensor.

- On the left side of the car, disconnect the ABS sensor connector and the brake pad wear indicator wire from the holders

- Disconnect and release the wires of the ABS sensor and brake pad wear warning lamp from the holders on the subframe.

- Place a jack under the engine frame.

- Remove the sub-frame reinforcements and successively replace the frame mounting bolts with threaded rods T. Av. 1233-01.

- Device T. Av. 1233-01 loosen the nuts so that the sub-frame drops 4-5 cm

- Remove the 2 bolts and heat shield from the brake lines.

- At four points, release the brake pipe and ABS wire from the holders.

- Disconnect the power steering lines.

- To disconnect the power steering lines on vehicles with Z engines, use Dir wrenches. 1282-01 and Dir. 1282-02. passing them through the wheel arch.

- On vehicles with Z and G engines, remove the power steering heat exchanger tube.

- Lower the sub-frame by 8 cm.

- Remove the steering gear heat shield.

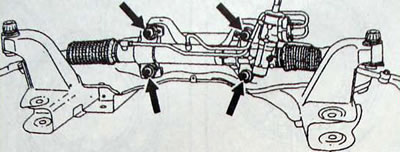

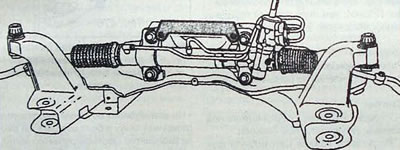

- Unscrew the 4 nuts securing the steering gear housing (pic. 9.10).

Pic. 9.10. Location of the steering gear housing mounting nuts

- Remove the steering gear assembly with rods. pulling it through the left wheel arch

Attention

When handling the steering gear, observe the following safety precautions:

- do not hold the steering gear by the covers;

- do not carry the steering gear by the pipelines;

- Protect the steering gear brackets from impacts;

- Protect the steering rods from impacts.

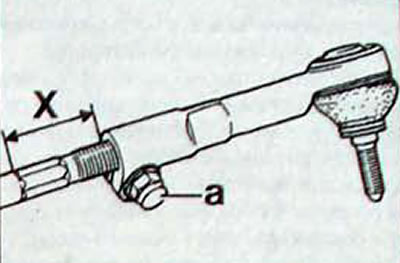

When replacing the steering gear, save the tie rod ends for future use. Unscrew the tie rod end clamping bolt one turn. Measure the size from the tie rod hexes to the tie rod ends and unscrew the tie rod ends (pic. 9.11).

Pic. 9.11. Size measurement location (X) from the tie rod hex to the tie rod end: a - tie rod end clamping bolt

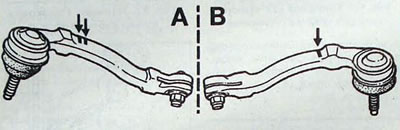

Pic. 9.12. Location of identification marks for the installation side of the tie rod ends: A - left tie rod end (2 cast tags); B - right tie rod end (1 cast tag)

Installation

- Installation is carried out in sequence. reverse withdrawal, taking into account the following.

- When screwing on tie rod ends, ensure equal dimensions (X. fig. 9.11) from tie rod hexagons to tie rod ends

- When installing, you must use new steering gear housing mounting nuts.

- Install the steering gear on the sub-frame and fixture Dir. 1303-01 for adjusting the position of the steering gear (pic. 9.13).

Pic. 9.13. Installation of fixture Dir. 1303-01 for blocking the steering gear on the sub-frame

- With the device Dir. 1303-01, tighten the four steering gear mounting nuts to the required torque.

- Install a heat shield.

- Before installing the sub-frame, attach the power steering pipes and tighten their fittings to the required torque, since after installing the sub-frame, access to the fittings will be difficult.

- Whenever you remove the subframe, replace all the nuts on the subframe mounting bolts and be sure to maintain the required tightening torques.

Note. Two washers (1, fig. 9.14) on the rear supports of the sub-engine frame ensure the alignment of the sub-engine frame assembly with the front suspension relative to the body when they are attached to the body. Therefore, be sure to ensure the correct position of these washers when starting tightening the fastening parts of the sub-engine frame from the left rear mounting point.

- Since the lower part of the steering column can move, it is necessary to adjust the position of the steering shaft universal joint yoke relative to the steering gear drive gear.

- Inside the car, install the Dir device on the lower part of the steering column. 1408 (rice. 9.6).

- Screw in the steering shaft universal joint fork connection bolt and tighten the bolt nut to the required torque.

- Remove fixture Dir. 1408.

- Fill the tank three-quarters full.

- With the engine running, slowly turn the steering wheel from lock to lock.

- Check the system for leaks and add fluid to the required level.

- Check the alignment of the front wheels and adjust the toe if necessary.