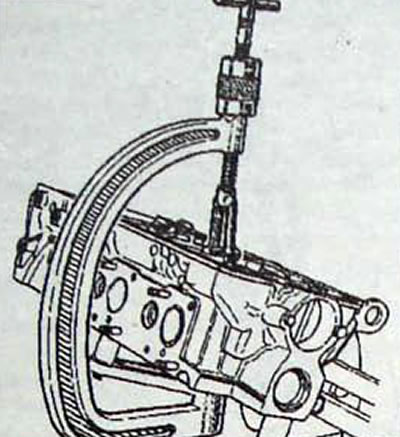

Pic. 2.28. Using a Valve Spring Compressor

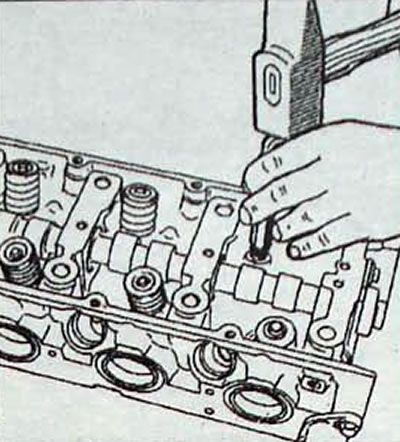

Pic. 2.29. Using a special tool to install the oil seal

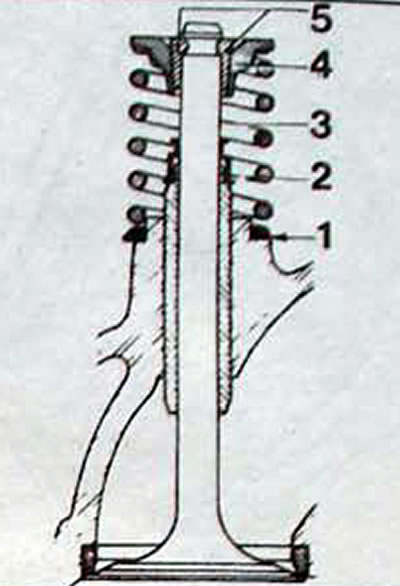

Pic. 2.30. Details of the valve installed in the cylinder head: 1 - spring seat; 2 - oil deflector cap; 3 - spring; 4 - upper spring plate; 5 - crackers

Disassembly

- Remove the camshaft thrust bearing mounting bolt.

- Remove the bolt, remove the longitudinal movement clamp and release the camshaft.

- Using a valve spring compressor, compress the first valve spring and remove the retainers.

- Smoothly loosen the spring compressor and remove it.

- Remove the spring plate, spring and spring seat and arrange the parts in the order they were removed.

- Remove the springs from the remaining valves in the same way.

- Remove oil seals and valves.

- Check the valve guides for wear. Insert the valve into the guide. The valve in the guide should move easily, without side play. To replace worn guides with new ones, special tools are required.

- Check the valve discs and valve seats for chipping and scorching. Signs of minor chipping on the valve and seat can be removed by grinding in, first with coarse grit and then with fine grit abrasive paste.

- If there are deep chipping marks, the valves should be ground on a valve grinder and the seats on a valve seat milling machine. To perform the last two types of work, you must contact specialists.

- After any treatment, clean the cylinder head.

- Neutralization of sodium contained in exhaust valves

- Before discarding the exhaust valves, the sodium they contain must be neutralized.

- Valves should be sawed in a dry room without the slightest contact with water (Do not use wet sharpened abrasive tools).

- Wear safety glasses.

- Saw the valve stems where they flare.

- Prepare a container filled with water and place it outside (approximately 10 liters of water per four valves).

- Immediately after sawing, immerse the sawn valves in water, avoiding splashing.

- Sodium reacts with water to form caustic soda, releasing hydrogen. The complete destruction of sodium is indicated by the cessation of hydrogen evolution (in the form of bubbles).

- Until the reaction is complete, keep the container away from fire (smoking is prohibited).

- Valves treated in this way can be discarded. Before. To remove them from the container, wear waterproof gloves.

- Rinse the container with plenty of water.

- If the solution gets on your skin or eyes, rinse them immediately with plenty of water and consult a doctor

Assembly

- Lubricate the first valve stem with engine oil and insert it into the guide. Install the oil seal.

- Install the spring seat, spring and spring plate

- Compress the valve spring with a spring compressor and insert the cotters into the top of the valve stem

- Smoothly remove the spring compressor and check that the crackers are in place.

- Install the remaining valves in the cylinder head in the same way.

- Once all the valves are in place, lightly tap the top of the valve springs with a plastic hammer to ensure that the valve springs are seated.

- Install the camshaft and camshaft retainer, however. do not tighten its fastening bolt