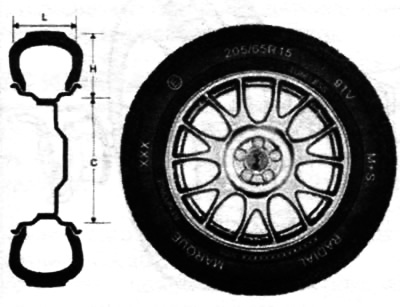

Tire identification

Tire marking example: 205/65 R 15 91 V.

|  |

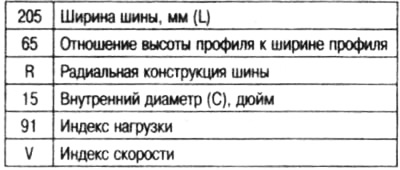

Tire speed indices

Tire pressure monitoring system (diagnostics)

The sensors begin to emit signals about a minute after the speed exceeds 20 km/h.

While driving, the sensors emit signals every minute.

The sensors remain active for 15 minutes after the car stops, then go into standby mode.

In standby mode, the sensor only emits a signal if the difference between two successively measured pressure values exceeds 68 mbar or if the pressure has changed by more than 68 mbar since the last signal was issued (as a result of tire cooling).

Tires are considered cold 1 hour 45 minutes after stopping the car.

The minimum detection time for tire air leaks is about 15 minutes.

Message «Inflate tires for freeway driving» issued (for reference), if the vehicle is driven at a speed of more than 170 km/h for 3 minutes and if the pressure in at least one tire is 400 mbar lower than specified for low speed. This message is not displayed at any speed when the tires are inflated for highway driving.

Threshold values of warning signals:

- cold tire pressure too high = tire pressure 700 mbar higher than prescribed;

- warm tire pressure too high = tire pressure 850 mbar higher than prescribed;

- tire pressure below normal = tire pressure below prescribed by - 400 mbar;

- tire pressure much lower than normal = tire pressure lower than prescribed by - 600 mbar;

- different tire pressures = the pressure difference between the left and right wheels of the same axle is greater than 500 mbar.

Messages displayed on the scoreboard:

- «Puncture, change wheel» + Lighting of the STOP signal lamp + Highlighting the image of the corresponding wheel on the display in the instrument panel + Sound signal;

- «Set the required tire pressure» + highlighting the image of the corresponding wheel on the scoreboard;

- «Inflate tires for freeway driving» + Highlighting images of all wheels on the scoreboard;

- «Tire sensor defective» + extinction of the image of the corresponding wheel;

- «Electronics failure» + signal lamp on «service» + Extinguishing images of the corresponding wheels on the scoreboard.

Tire pressure information is not displayed on the instrument panel.

Tire pressure

Tire pressure value see Section «Vehicle operation and maintenance».

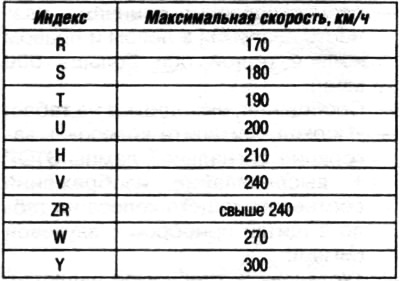

Wheel balancing

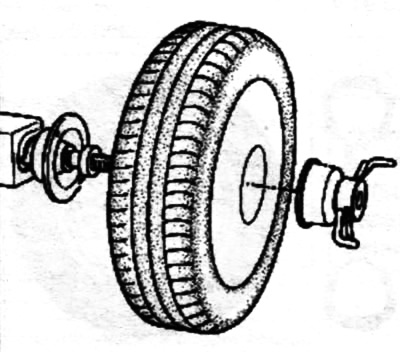

To accurately reproduce the conditions of installation of the wheel on the car, be sure to install a bushing on the balance stand (1) with a diameter of 60 mm.

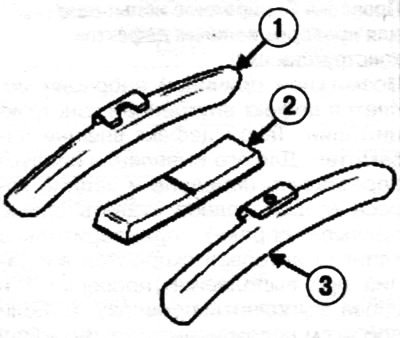

There are 3 types of balancing weights:

1 - alloy wheel with a rim;

2 - alloy wheel without flange;

3 - stamped steel disk with a rim.

Place the vehicle on a lift immediately after the road test.

Loosen the wheel bolts. Raise the vehicle.

Release the parking brake.

Make sure the wheel is free from impact damage (if there are deformations, replace the damaged parts).

Turn the wheel with the valve up. Install the wheel wrench.

Loosen the wheel bolts and remove the wheel.

Be sure to clean the bearing surfaces of the wheel and rim (or brake drum).

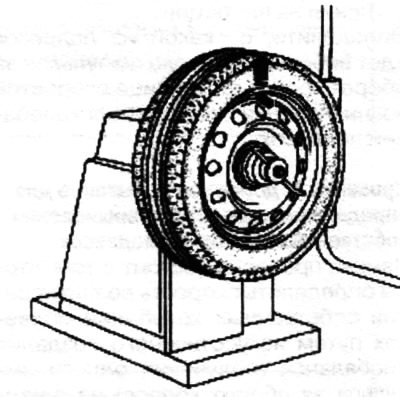

Keep the bearing surface of the balancer and all centering elements clean (ring, pusher pad, etc.). Take care not to scratch the rim (light alloy) wheel locking device. Install the wheel on the stand.

Some light alloy wheels require a 200mm adapter to secure the fit.

Fasten the wheel.

When turning on the balancing stand and entering the wheel parameters, turn on the balancing mode «FIN» (accurate).

If necessary, remove small stones from the tire tread pattern. Enter individual wheel parameters when turning on the wheel balancer.

Turn on the stand and check the wheel imbalance, which should be 0 g in each wheel plane.

If the imbalance exceeds the specified values, remove the previously installed balancing weights from the wheel and balance the wheel again so that the imbalance does not exceed 0 g in each wheel plane.

Attention. To ensure that the balance weights do not come off, only balance weights that match the vehicle's rims should be used.