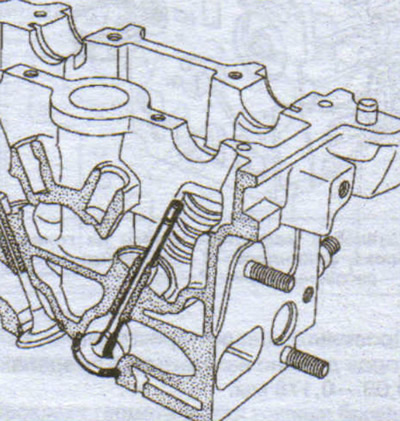

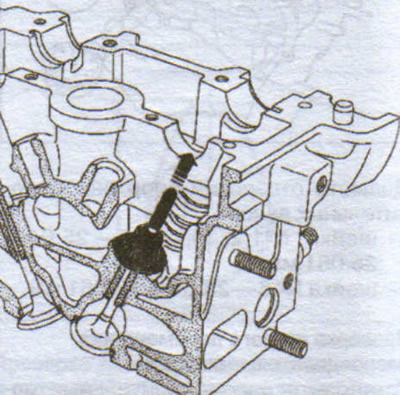

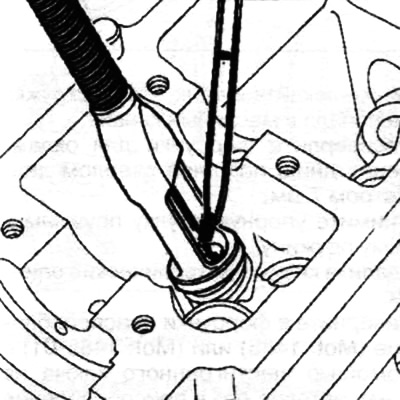

Put on the tip of the tool (Mot. 1511) on the valve stem (the inner diameter of the tip must be equal to the diameter of the rod).

Keep the valve pressed against the seat.

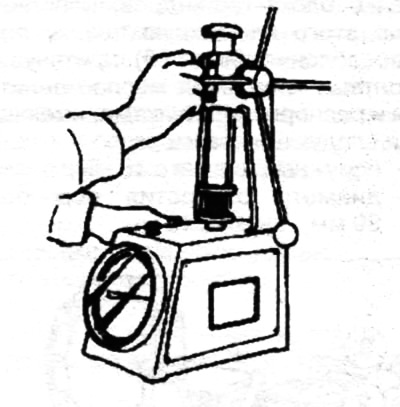

Spring calibration check

|  |

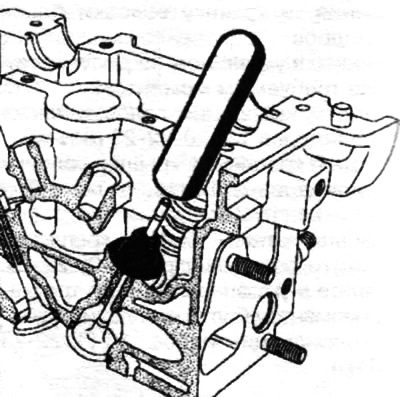

Install the oil seal (not oiled) on the tip.

Slide the slinger cap until it passes over the tip.

Remove the tip.

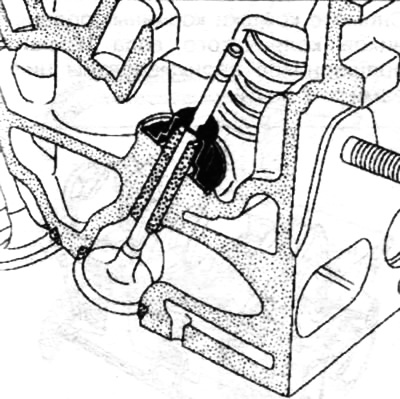

Install the mandrel on the oil seal.

|  |

Note. The inner diameter of the mandrel must match the diameter of the valve stem. In addition, the lower part of the mandrel should partially abut against the slinger cap, which serves as a support washer for the valve spring.

Press on the slinger cap by tapping the top of the mandrel with your palm until the slinger cap contacts the cylinder head.

Repeat the above steps for all valves.

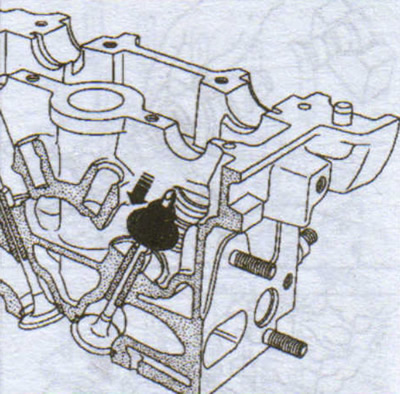

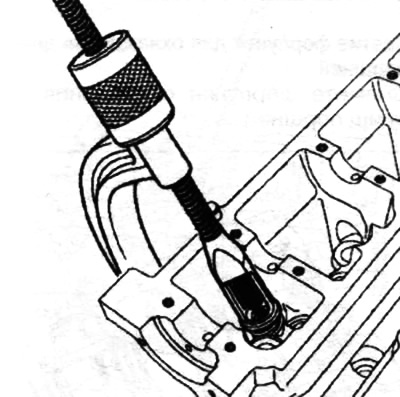

Install springs and plates.

Insert crackers with curved tongs.

Install the thermostat block with a new gasket on the cylinder head.

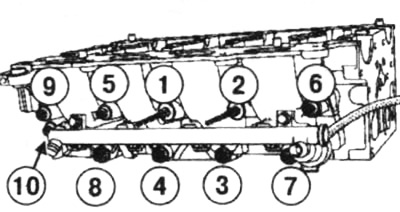

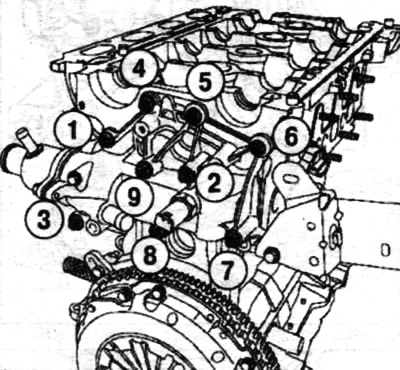

Tighten in the order shown in the figure to the required torque (10 Nm) bolts of fastening of the block of the thermostat on a head of the block of cylinders.

Install the exhaust manifold with a new gasket.

Tighten in the order shown in the figure to the required torque (23 Nm) exhaust manifold nuts.

Install the exhaust manifold heat shield.

Torque tighten (1 Nm) exhaust manifold heat shield bolts.

Attention. Make sure the exhaust manifold heat shield is securely seated between the oxygen sensor and the manifold (to avoid overheating which could destroy the wiring of the upstream oxygen sensor).

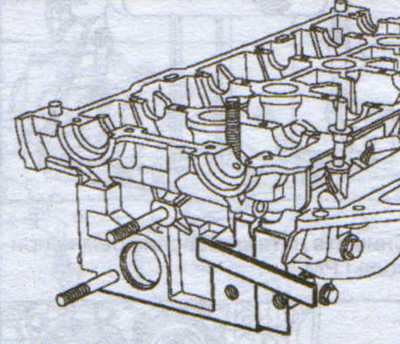

Torque tighten (4.5 Nm) oxygen sensor with tool (Mot. 1495). Install the inner timing case spacer.

Install the injector body shims with a new gasket.

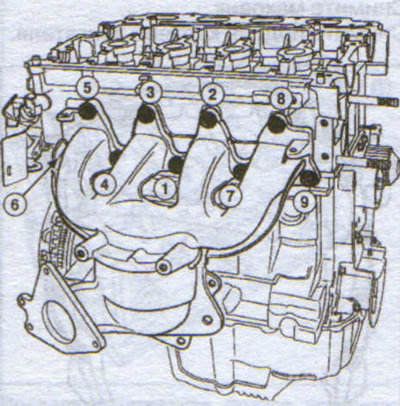

Install the oxygen sensor. Align the lining of the injector bodies with respect to the cylinder head (from the timing drive).

Align the mating planes of the lining of the injector bodies with respect to the cylinder head. Tighten in order to the correct torque (21 Nm) bolts of fastening of a lining of cases of atomizers.

|  |