Torque tightening

The most commonly used method. It consists in wrapping until a given counteracting moment, called the tightening torque, is obtained.

A significant part of the tightening torque falls on the friction torques (under the head and in the thread) and, a small amount, is used to create a useful tightening torque (for voltage).

With this tightening method, a significant stress spread is obtained due to changes in the friction coefficients for different joints and inaccuracies of the methods and the inability to provide the specified torque with the tools used.

Angle tightening

The principle of this method is to connect the parts of the assembly by means of a docking moment (about 25-30% of the final moment), then in a turn to a given angle. This method almost does not depend on the friction forces of the bolted connection and gives more accurate results than torque tightening.

Compliance with tightening torques and angles

If the torques and tightening angles of bolted connections are specified in the description of the removal and installation operations, they must be strictly observed. Tightening is done with the appropriate tool (torque wrench, goniometric disc). Failure to comply with tightening torques and angles can lead to reduced safety, malfunctions that make further operation of the vehicle impossible, and increased noise and friction. For other bolted connections, tightening is allowed without checking the tightening torque value (using standard keys). However, the corresponding tightening torque is listed in the table of standard tightening torques.

Recommended tool for controlled tightening

For controlled tightening, torque wrenches are used that provide tightening in the range of 4-400 Nm, as well as a goniometer disk. Torque wrenches with a limiting torque or electronic ones are used.

For example:

- torque wrench 4-40 Nm;

- torque wrench 20-100 Nm;

- torque wrench 80-400 Nm;

- angle disc.

The torque wrenches used must comply with ISO 6789. The wrenches must be regularly calibrated to the supplier's specifications by appropriate means.

Using a torque wrench with a limiting tightening torque

When the limit force is reached, the release mechanism of such a tool causes the key to break or turn off.

The force limit is determined by the adjustment of the wrench, but also depends on how it is used.

If the regulations are followed, the tightening accuracy with a torque wrench with a tightening torque limit is±15%.

When working with such a tool, the following rules must be observed:

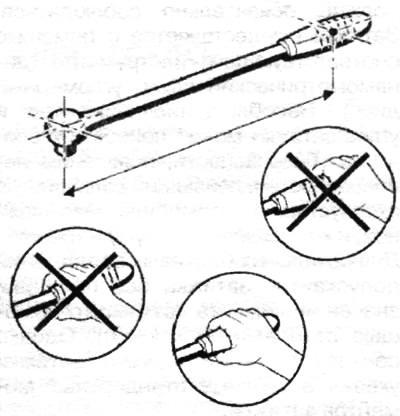

lever arm

- you need to take the handle in the middle (if the hand position on the handle is incorrect, the response threshold changes);

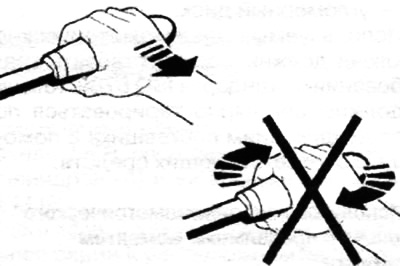

- gently and without jerks pull the key without twisting it. Fast tightening speed as well as jerking are the main causes of overtightening. The twisting force applied to the key changes its response threshold;

- hold the key on the bolt with minimal force. When force is applied to the key head, the threshold for its operation changes;

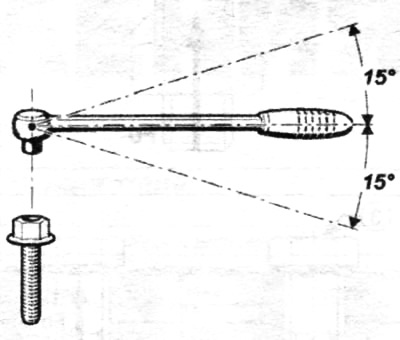

- apply the tightening torque perpendicular to the fastening axis, maintaining a tolerance of±15°with respect to the perpendicular to the fastening axis. The non-perpendicularity of the wrench with respect to the fastening axis is the cause of insufficient tightening.

- stop tightening as soon as the key works. Further tightening after the key has actuated results in overtightening.

|  |

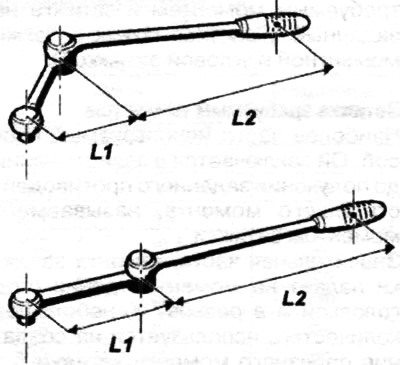

When changing the key length (adding pen extension, tip) it is necessary to adjust the key in the new version. When the key length is changed, its triggering threshold changes.

Use the formula:

WITH1 = C0 to L2 / (L1+ L2).

WITH0 - applied force.

WITH1 - adjusting force displayed on the key.

L1 - the length of the extension.

L2 - key length.

Attention. During controlled work, it is prohibited, except as specifically stated in the repair procedure, to use a universal joint (cardan type). When using a cardan joint, there is a difference between the adjusting torque of the wrench and the actual applied torque.

Before putting the key into storage, fully unload the adjusting spring. If the wrench is stored with the spring under tension, tightening accuracy is lost.

Using electronic torque wrenches

The reading of the torque and, depending on the tightening angle model, is carried out directly on such tools.

If the rules are followed, the tightening accuracy with an electronic torque wrench is±5%.

The accuracy of electronic torque wrenches does not depend on the position of the performer's hand on the wrench handle.

In this case, use the key carefully and stop tightening when the required value appears on it.