Fill the gearbox with fluid and check the level.

Filling with automatic transmission fluid

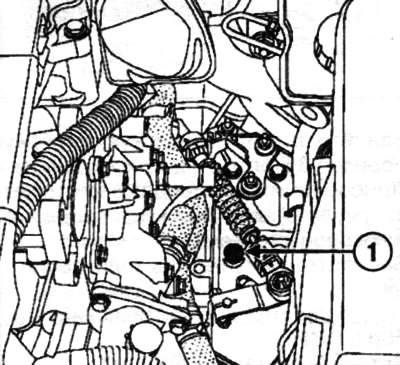

Filling is carried out through the appropriate opening (1).

Use a 15/1 mesh filter funnel to prevent contamination.

Park the vehicle on a level, level surface.

Disconnect the wires from the battery terminals, starting with the negative terminal.

Disconnect the wiring harnesses from the computer.

Loosen the bolts securing the battery tray.

Remove the battery tray and ECU bracket.

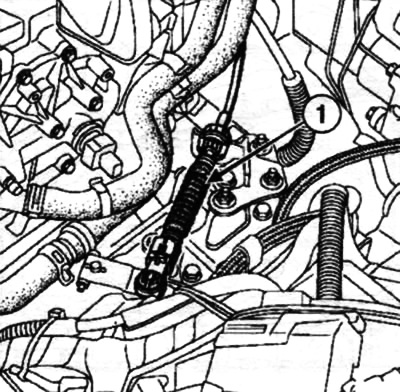

Remove cable (1) accelerator drive.

Disconnect the cable from the lever on the gearbox:

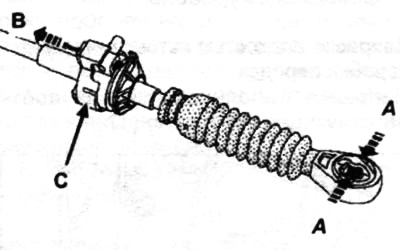

- squeeze the tip of the cable at points A;

- pull the lock in direction B;

- lift the accelerator cable at point C.

|  |

Fill the automatic transmission with 3.5 liters of fresh fluid. Attach the wires to the battery terminals, starting with the positive terminal.

Start the engine at idle

Connect the diagnostic tool («CLIP»).

Enter into a dialogue with the automatic transmission computer.

Watch the temperature of the oil in the box.

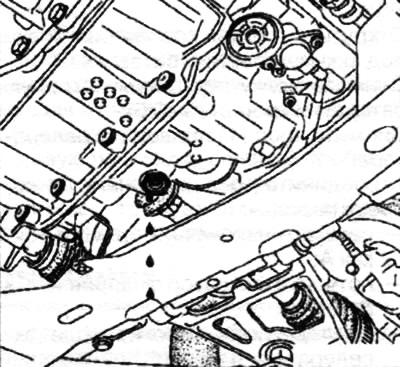

When the temperature reaches 60°C±1, unscrew the plug of the control hole.

Install a container, if the oil does not flow out or the amount of leaked oil is less than 0.1 liters, stop the engine.

Add 0.5 liters of fluid, let the gearbox cool down to 50°C and start the engine at idle. Reconnect the diagnostic tool («CUP») and enter into a dialogue with the automatic transmission computer.

Monitor the fluid temperature parameter in the automatic transmission.

When the temperature reaches 60°C±1, unscrew the control hole plug.

Place a container under the car to collect the oil.

Repeat these operations until more than 0.1 liter of liquid has been poured into the container.

Screw on the control hole plug.

Torque tighten (35 Nm) check hole plug.

Note. In the event of a fluid change, the electronic fluid life counter must be reset (it is built into the computer).

Register oil change date by command: CF074 «Recording the date of fluid change in the gearbox» using a diagnostic tool.

Note. In cases of repair work on an auto transmission, barely blowing parts are subject to mandatory replacement:

- self-locking nuts;

- sealing gaskets;

- rubber pads;

- torque converter bolts.