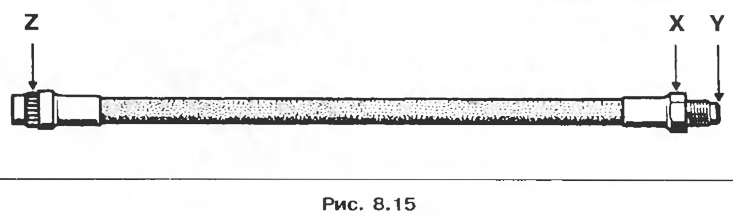

Tightening torques, Nm

X = 15; Z = 13

Attention! For safety reasons and to avoid kinking of the brake hoses, as well as the possibility of them touching the suspension parts, the work procedure described below must be followed.

4. Remove the thermostat housing (2 bolts).

5. Remove the vacuum pump (2 bolts, 2 nuts).

6. When replacing the pump, replace the drive pin.

Installation

1. Installation is made in an order, the return to removal.

2. Remove air from the brake circuit.

Examination

With a warm engine at 4000 rpm, the minimum vacuum must be 700 mbar (525 mm. rt. Art.) within 3 sec.

Removing

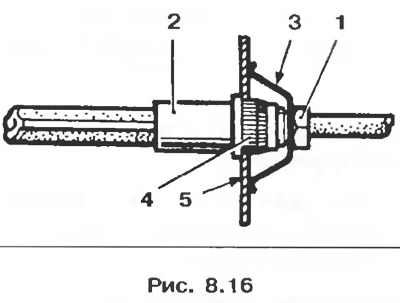

1. Loosen union nut 1 (nipple wrench), connecting the tube and hose 2, so that the spring 3 is completely released, which would make it possible to remove the hose tip from the slotted hole 4.

2. Remove the hose from the brake caliper and, if necessary, remove the brake caliper.

Installation

1. Install the caliper on the brake mechanism and screw the hose into the hole on the brake caliper.

2. Then tighten the hose end with a torque of 15 Nm.

Brake pipes are installed when the axle is in place:

- wheels installed (suspension in place);

- bridge leveled (steered wheels in straight ahead position).

3. Fix the nipple end of the hose on the bracket 5 without twisting the hose and check that the end piece 4 fits freely into the slotted hole of the bracket.

4. Install spring 3.

5. Install the tubing onto the hose, being careful not to twist the tubing while screwing the tubing onto the hose.

6. Torque tighten the union nut.

7. Remove air from the brake circuit.