Share with friends:

Gasoline engine E7J car Renault Kangoo 1

E7J petrol engine — general information

Table 3.1 Pic. 3.1a. Sectional view and tightening torques, Nm: 1 - Nut of the tension roller of the timing mechanism drive: tightening torque 50 Nm; 2 - Bolt and nut M6: tightening torque 10 Nm (bolt M8: tightening...

Table 3.1 Pic. 3.1a. Sectional view and tightening torques, Nm: 1 - Nut of the tension roller of the timing mechanism drive: tightening torque 50 Nm; 2 - Bolt and nut M6: tightening torque 10 Nm (bolt M8: tightening...

Removal and installation of the engine

Required special tool Mot. 1040-01 Trolley for removal and installation of the power unit. Mot 1159 Tool for fixing the engine to the subframe. Mot. 1202, Mot. 1448 Pliers for flexible clamps. Mot. 1311-06 Tool for...

Required special tool Mot. 1040-01 Trolley for removal and installation of the power unit. Mot 1159 Tool for fixing the engine to the subframe. Mot. 1202, Mot. 1448 Pliers for flexible clamps. Mot. 1311-06 Tool for...

Oil pan

Required special tool Mot. 1233-01 Threaded rods for removing the subframe. Tightening torques, Nm Subframe front mounting bolts: 62. Rear subframe bolts: 105. Bolts of fastening of the pallet of a crankcase of the...

Required special tool Mot. 1233-01 Threaded rods for removing the subframe. Tightening torques, Nm Subframe front mounting bolts: 62. Rear subframe bolts: 105. Bolts of fastening of the pallet of a crankcase of the...

Drive belt gas distribution mechanism

Required special tools and fixtures Mot. 591-02 Magnetic base pointer for angular bolt tightening. Mot. 591-04 Angle wrench for tightening bolts. Mot. 1135-01 Fitted for tensioning the gas timing belt. Mot. 1273 Belt...

Required special tools and fixtures Mot. 591-02 Magnetic base pointer for angular bolt tightening. Mot. 591-04 Angle wrench for tightening bolts. Mot. 1135-01 Fitted for tensioning the gas timing belt. Mot. 1273 Belt...

Cylinder head gasket

Required special tools and fixtures Mot. 588 Cylinder liner retainer. Mot. 591-02 Magnetic base pointer for angular bolt tightening. Mot. 591-04 Angle wrench. Mot. 1159 Device for supporting the engine on the subframe....

Required special tools and fixtures Mot. 588 Cylinder liner retainer. Mot. 591-02 Magnetic base pointer for angular bolt tightening. Mot. 591-04 Angle wrench. Mot. 1159 Device for supporting the engine on the subframe....

Cylinder head

Technical data 1. Cylinder head Cylinder head height mm: H = 113.5. The maximum allowable deformation of the mating surface, mm: 0.05. Combustion chamber volume with valves and spark plug, cm 3 : 26,25±0,6. 2. Valve...

Technical data 1. Cylinder head Cylinder head height mm: H = 113.5. The maximum allowable deformation of the mating surface, mm: 0.05. Combustion chamber volume with valves and spark plug, cm 3 : 26,25±0,6. 2. Valve...

Crank mechanism

1. Pistons The piston pin is pressed into the upper head of the connecting rod and rotates freely in the piston bosses. Fitting direction: Arrow points towards flywheel. SMP piston Piston Arrow 1 indicates installation...

1. Pistons The piston pin is pressed into the upper head of the connecting rod and rotates freely in the piston bosses. Fitting direction: Arrow points towards flywheel. SMP piston Piston Arrow 1 indicates installation...

Coolant temperature sensor

The thermal resistance transmits to the receiver a signal corresponding to a change in resistance depending on the temperature of the coolant, and if the temperature exceeds 118°C, the signal lamp on the instrument...

The thermal resistance transmits to the receiver a signal corresponding to a change in resistance depending on the temperature of the coolant, and if the temperature exceeds 118°C, the signal lamp on the instrument...

Elements of the injection system

Table 3.6 * At 2500 rpm, the CO content should not exceed 0.3%. ** When the coolant temperature is above 80°C after the engine has been running steadily at 2500 rpm for approximately 30 seconds. The check should be...

Table 3.6 * At 2500 rpm, the CO content should not exceed 0.3%. ** When the coolant temperature is above 80°C after the engine has been running steadily at 2500 rpm for approximately 30 seconds. The check should be...

Throttle block

Tightening torques, Nm Throttle valve mounting bolt 10. Removing 1. Disconnect the battery. 2. Remove the air filter. 3. Remove air duct 1. 4. Disconnect the throttle cable. 5. Disconnect the IAC 2 stepper motor...

Tightening torques, Nm Throttle valve mounting bolt 10. Removing 1. Disconnect the battery. 2. Remove the air filter. 3. Remove air duct 1. 4. Disconnect the throttle cable. 5. Disconnect the IAC 2 stepper motor...

Intake manifold

Tightening torques, Nm Bolt and nut of fastening of an inlet collector 20 Removing 1. Remove the air filter. 2. Remove the fuel distribution rail. 3. Raise the car. 4. Remove bracket 1 (to access the bracket bolt on the...

Tightening torques, Nm Bolt and nut of fastening of an inlet collector 20 Removing 1. Remove the air filter. 2. Remove the fuel distribution rail. 3. Raise the car. 4. Remove bracket 1 (to access the bracket bolt on the...

Fuel distribution ramp

Attention! When disconnecting the fuel line, take protective measures (with a rag) from fuel emissions due to the presence of residual pressure in the system. Removing 1. Disconnect the battery. 2. Remove the air...

Attention! When disconnecting the fuel line, take protective measures (with a rag) from fuel emissions due to the presence of residual pressure in the system. Removing 1. Disconnect the battery. 2. Remove the air...

Fuel filter

See 2.18. Fuel filter engine D7F .

See 2.18. Fuel filter engine D7F .

Fuel tank

See 2.19. Fuel tank of D7F engine .

See 2.19. Fuel tank of D7F engine .

Fuel pump assembly with fuel level sensor

See 2.20. Fuel pump assembly with D7F engine fuel level sensor. Fuel pressure test Required special tool Mot. 1311-01 Portable Fuel Pressure Monitor (with built-in pressure gauge 0-10 bar). Mot. 1311-04 Tee. Attention!...

See 2.20. Fuel pump assembly with D7F engine fuel level sensor. Fuel pressure test Required special tool Mot. 1311-01 Portable Fuel Pressure Monitor (with built-in pressure gauge 0-10 bar). Mot. 1311-04 Tee. Attention!...

Fuel vapor recovery system

Pic. 3.113. Scheme of the fuel vapor recovery system: 1 - Intake manifold; 2 - Fuel vapor absorber; 3 - Solenoid valve with control according to the law of cyclic opening; 4 - Throttle valve block; R - The pipeline...

Pic. 3.113. Scheme of the fuel vapor recovery system: 1 - Intake manifold; 2 - Fuel vapor absorber; 3 - Solenoid valve with control according to the law of cyclic opening; 4 - Throttle valve block; R - The pipeline...

Oil vapor recovery system

1 - Cylinder head; 2 - Collector; 3 - The pipeline of the oil vapor recovery system, connected to the over-throttle space of the throttle valve (the circuit is used for medium and heavy loads); 4 - The pipeline of the...

1 - Cylinder head; 2 - Collector; 3 - The pipeline of the oil vapor recovery system, connected to the over-throttle space of the throttle valve (the circuit is used for medium and heavy loads); 4 - The pipeline of the...

An exhaust manifold

Tightening torques, Nm Manifold mounting bolt 20 Removing 1. Remove multifunction bracket 1 2. Disconnect the spacer 2 between the exhaust manifold and the exhaust system. 3. Remove heat shield 3. 4. Remove the exhaust...

Tightening torques, Nm Manifold mounting bolt 20 Removing 1. Remove multifunction bracket 1 2. Disconnect the spacer 2 between the exhaust manifold and the exhaust system. 3. Remove heat shield 3. 4. Remove the exhaust...

Exhaust gas exhaust system

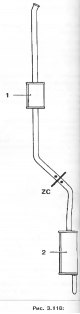

See 2.24. Exhaust system of the D7F engine. 1 - Front muffler; 2 - Main muffler; ZC - Pipe cutting zone.

See 2.24. Exhaust system of the D7F engine. 1 - Front muffler; 2 - Main muffler; ZC - Pipe cutting zone.

Generator — general information

Type: Valeo A 11 VI 87. Rated output current: 75 A. Diagnostics After 15 minutes warm up (in steady state) at a voltage of 13.5 V at the terminals. Table 3.9 These vehicles are equipped with alternators with internal...

Type: Valeo A 11 VI 87. Rated output current: 75 A. Diagnostics After 15 minutes warm up (in steady state) at a voltage of 13.5 V at the terminals. Table 3.9 These vehicles are equipped with alternators with internal...

Starter — general information

Type: D6 RA 73 Removal and installation 1. Place the vehicle on a two post lift. 2. Remove the battery. 3. Remove the injection computer bracket by disconnecting the 55-track connector and the inertial switch connector....

Type: D6 RA 73 Removal and installation 1. Place the vehicle on a two post lift. 2. Remove the battery. 3. Remove the injection computer bracket by disconnecting the 55-track connector and the inertial switch connector....

Static ignition system

Elements of the ignition system: injection computer (the power stage of the ignition module is built into the computer); two ignition coils with two leads; four spark plugs; noise filter capacitor 4. Principle of...

Elements of the ignition system: injection computer (the power stage of the ignition module is built into the computer); two ignition coils with two leads; four spark plugs; noise filter capacitor 4. Principle of...

This section is available on: russian, bulgarian, belarusian, ukrainian, serbian, croatian, romanian, polish, slovak, hungarian

Link to this section in different formats

TEXTHTMLBB Code

- General information

- User manual

- Maintenance

- Power unit

- Petrol engine D7F

- Petrol engine E7J

- Diesel engine F8Q

- Transmission

- Clutch

- Car gearbox

- Drive shafts

- Chassis, running gear

- Car suspension

- Steering

- Brake system

- Body and interior

- Exterior and interior

- Doors, locks and windows

- Electrical equipment

- Equipment and devices

- Electrical circuits

RenaultBook.ru © 2018–2024 | Mobile version | News and articles | Sitemap: EN BG BY UA RS HR RO PL SK HU | Administration | Site search | Bookmark

Duster 1 (2009-2017) | Fluence 1 (2009-2020, petrol) | Kangoo 1 (1997-2007) | Laguna 2 (2001-2007) | Logan 1 (2004-2012, petrol) | Logan 2 (2012-2020) | Megane 1 (1995-2002) | Megan 2 (2002-2009, petrol) | Sandero 1 (2007-2012) | Scenic 1 (1996-2003) | Symbol 1 (1999-2008, petrol) | Symbol 2 (2008-2013, petrol) | Renault 19 (1988-1996) | Espace I and II (1984-1996) | Espace III (1996-2002) |