As their name suggests, these body parts are very strong and resilient. They are stamped using a special technology. When repairing, they cannot be straightened in the usual ways used in body work.

Note. It is strongly not recommended to heat these body parts for straightening. since thermal exposure will lead to the loss of the original properties of the metal). Therefore, damaged parts must be replaced either completely or partially by cutting them. To remove the factory weld points on these parts, it is recommended to use special drills such as "HSS". If they are not available, it is best to use a grinder or a tungsten carbide cutter.

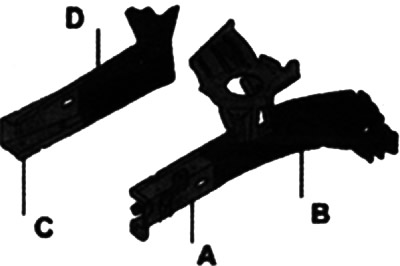

The body frame of this car also includes elements made by laser butt welding, and the component parts of the element can have different thicknesses, and sometimes different properties, such as. for example, the front spar.

- Part B: very high tensile metal panel HE 450 M, 1.8 mm thick.

- Part C: high tensile metal panel XE 280 P 1.5 mm thick.

- Part D: high tensile metal panel HE 450 M, 2.5 mm thick.

If, in the detailed description of the technique, two sheet thicknesses are indicated, this means that this part consists of two butt-joined elements at the factory. The correspondences of the thickness value are established by moving from the outer surface of the part to the interior of the car (in the direction of impact).