- elevated (compared to usual) noise when engaging and disengaging the clutch;

- jerks during clutch operation;

- incomplete engagement of the clutch (clutch «slips»);

- incomplete clutch disengagement (clutch «leads»).

Note. If the clutch fails, we recommend replacing all its elements at the same time (driven and driven discs, clutch release bearing), since the work of replacing the clutch is laborious, and the life of undamaged clutch elements has already been reduced and, if they are installed again, it may be necessary to replace the clutch again after a relatively short run.

You will need: key «at 11» (more comfortable socket head), screwdriver...

... mandrel for centering the driven disk (can be made from the input shaft of the gearbox by removing the gears). A commercially available mandrel for front-wheel drive VAZ vehicles is also suitable.

1. Remove the gearbox (see «Removal and installation of a transmission»).

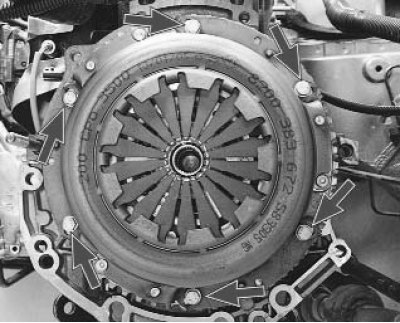

Note. This is how the clutch cover bolts to the engine flywheel are located.

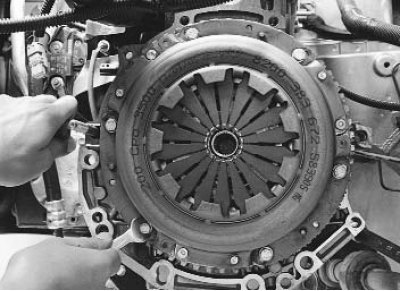

Note. If you install the old pressure plate, mark in any way (e.g. paint) the relative position of the disc housing and the flywheel to set the pressure plate in its original position (to maintain balance).

2. Holding the flywheel with a screwdriver (or mounting spatula) from turning, unscrew the six bolts securing the clutch pressure plate housing to the flywheel. Loosen the tightening of the bolts evenly: each bolt one turn of the wrench, moving from bolt to bolt in diameter.

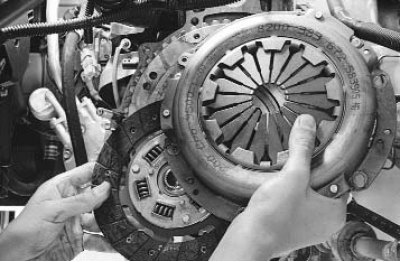

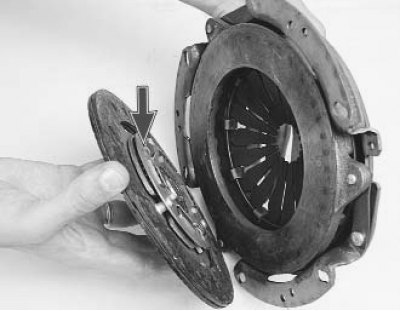

3. Remove the clutch pressure and driven discs from the flywheel while holding the driven disc.

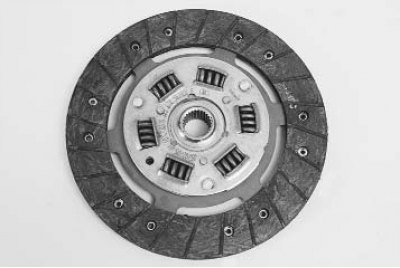

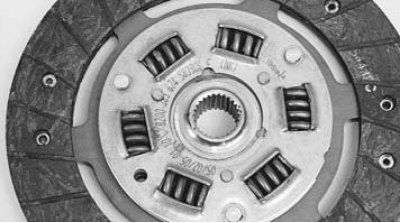

4. Examine a conducted disk of coupling. Cracks on the details of the driven disk are not allowed. Check the degree of wear of the friction linings. If the rivet heads are recessed by less than 0.2 mm, the surface of the friction linings is oily, or the rivet connections are loose, then the driven disk must be replaced.

Note. If overlays of a conducted disk are greased, check up a condition of an epiploon of a primary shaft of a transmission. It may need to be replaced.

5. Check up reliability of fixing of damper springs in sockets of a nave of a conducted disk, trying to move them by hand in sockets of a nave. If the springs move easily in their seats or are broken, replace the disc.

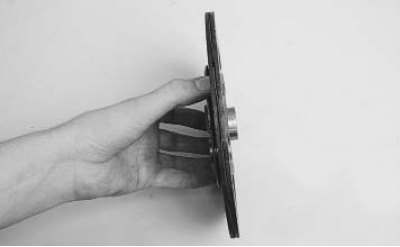

6. Check up beating of a conducted disk if its warpage is found out at visual survey. If the runout is greater than 0.5 mm, replace the disc.

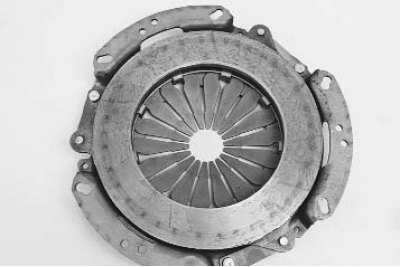

7. Inspect the friction surfaces of the flywheel and pressure plate, paying attention to the absence of deep scratches, scuffs, nicks, obvious signs of wear and overheating. Replace defective units.

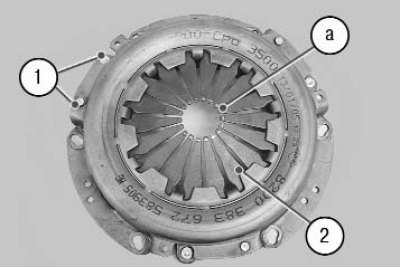

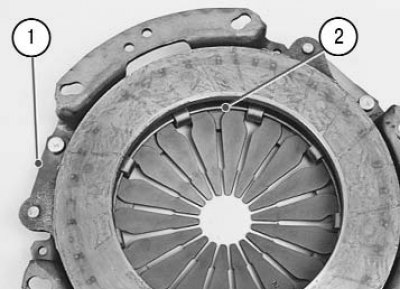

8. When loosening riveted connections 1 parts of the casing and pressure plate, replace the pressure plate assembly. Visually evaluate the condition of the diaphragm spring 2 of the pressure plate. The presence of cracks on the diaphragm spring is not allowed. Places a of contact between the petals of the spring and the clutch release bearing must be in the same plane and not have obvious signs of wear (wear should not exceed 0.8 mm). Otherwise, replace the pressure plate assembly.

9. Examine connecting links 1 of a casing and a disk. If the links are deformed or broken, replace the pressure plate assembly. Visually assess the condition of the support rings 2 of the pressure spring. Rings must be free of cracks and signs of wear. Otherwise, replace the pressure plate assembly.

10. Before installation of coupling check up ease of movement of a conducted disk on splines of a primary shaft of a transmission. If necessary, remove the causes of seizing or replace defective parts.

11. Lubricate the splines of the driven disc hub with refractory grease.

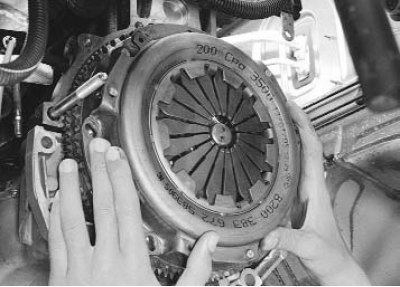

12. When mounting the clutch, first install the driven disk using a mandrel...

Note. Install the driven disc so that the protruding part of the disc hub (shown by arrow) was directed towards the diaphragm spring of the clutch housing.

13.... and then on three centering pins - the casing of the pressure plate and screw in the bolts securing the casing to the flywheel. Screw the bolts evenly, one turn of the wrench each, alternately moving from bolt to bolt in diameter. Bolt tightening torque 12 Nm (1.2 kgf·m).

14. Remove the mandrel and install the gearbox.

15. Install the lower end of the clutch release cable to the gearbox and adjust the length of the threaded cable end (see «Replacing and adjusting the clutch release cable»).