Removal and installation of fuel injectors

Removing fuel injectors

1. Disconnect the negative battery terminal.

2. Remove the fuel line (s) high pressure between fuel rail and injector (kami).

3. Clean the fuel return line connectors at the fuel injectors.

Caution: To prevent corrosion or damage, care must be taken to protect surfaces that may be exposed to escaping fuel.

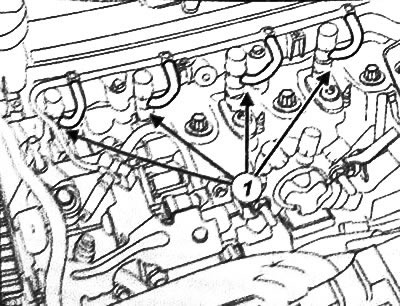

4. Disconnect fuel return lines (1) from fuel injectors.

5. Install suitable plugs on the return ports of the fuel injectors. Also plug the fuel return lines.

Note: If one or more fuel injectors are to be reused, mark the position of the injectors in relation to the respective cylinders before removal. After removing the nozzle, place it in a sealed bag.

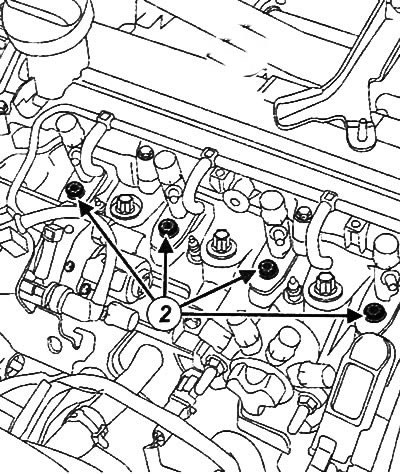

6. Loosen the bolt (2) corresponding fuel injector bracket (nok).

7. Remove bracket (s) fuel (s) nozzles (OK).

8. Remove the spring washer located at the bottom of the fuel (nyh) nozzles (nok).

Note: If the fuel injector is stuck on and cannot be removed, turn it by the flat surfaces of the bracket with an open end wrench.

9. Install a suitable plug on the end of the fuel injector.

Fuel injector cleaning

Attention:

- It is strictly forbidden to clean fuel injectors with a metal brush, sandpaper, ultrasonics.

- Wear leak-resistant nitrile gloves when handling.

1. Soak the fuel injectors in a special cleaner.

2. Clean the fuel injectors with lint-free wipes or a toothbrush.

3. Dry the fuel injectors.

Cleaning the fuel injector sockets

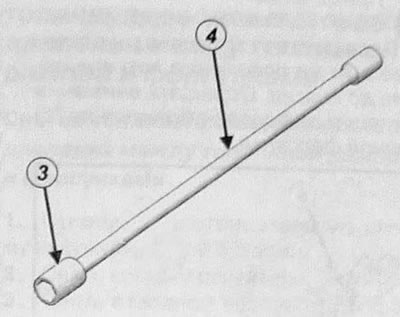

1. Install 11mm nozzle (3) (the outer diameter of the nozzle is equal to the diameter of the washer) to extension cord (4).

2. Wrap the cleaning cloth around the nozzle extension.

3. Moisten the cleaning cloth with the cleaning agent.

4. Insert the wrapped extension with the nozzle into the fuel injector socket.

5. Clean the fuel injector seat.

Note: Turn the extension with the nozzle into the injector socket.

6. Remove the cleaning pad from the slot.

7. Insert a large-diameter Phillips screwdriver (over 8 mm) into the fuel injector socket to block the opening to the combustion chamber.

8. Blow out scale residues with compressed air.

9. Remove the screwdriver and repeat the cleaning procedure with a cloth as described above.

Installing fuel injectors

Attention:

- You must remove the plugs from the components and remove the components from the packaging immediately before installing the component.

- Be sure to replace the fuel injector seals with new ones after each removal.

1. Clean the fuel injectors and their seats in the cylinder head.

2. Install a new spring washer.

3, Install the fuel injector.

4. Install the fuel injector bracket.

5. Install the fuel injector bracket bolt.

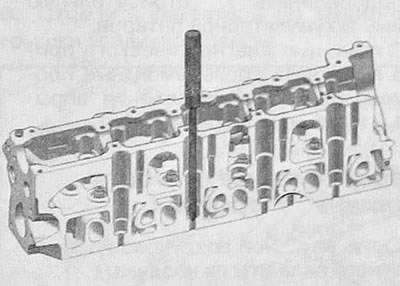

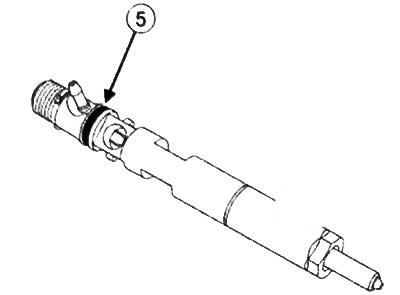

Note: If the fuel injector is being reused, install it in the same position as it was before removal. Pay attention to alphanumeric characters (5) fuel injector.

6. Tighten the fuel injector bracket bolt to 28 Nm.

7. Remove the plug from the fuel injector return port.

8. Install high pressure fuel line between fuel rail and injector.

9. Connect the fuel return line to the injector.

Note: Install all other fuel injectors in the same way

10. Check for fuel leaks.

11. Connect the negative battery terminal.

12. Using a scan tool, perform post-repair procedures for the injection control unit and fuel injectors.

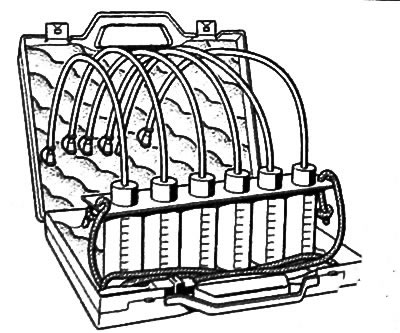

Fuel injector leak test

1. Remove the air intake duct from the intercooler.

2. Remove the fuel rail protection.

3. Connect the four clear hoses of the fuel injector leak tester to the fuel injector return ports.

Note: The hoses must be fitted onto the return fittings of the fuel injectors with a tight fit. If, due to deformation of the hose, it fits too loosely on the fitting, it is necessary to cut off the stretched part of the hose to ensure a tight fit.

4. Insert the ends of the connected transparent hoses into the measuring beakers of the device.

5. Install the intercooler outlet duct clamp.

6. Crimp the intercooler outlet duct at the damper valve.

7. Connect the boost pressure sensor connector.

8. Install the turbocharger outlet duct clamp.

9. Crimp the intercooler duct between the turbocharger and intercooler at the turbocharger outlet port.

10. Connect independent starter.

11. Connect the autonomous starter to the car's on-board network.

12. Connect the diagnostic tool.

13. Run command VP036: "Fuel cut" ("Fuel supply inhibition").

14. Turn on the starter for 15 seconds.

15. Verify that the amount of fuel return from each injector is greater than 15 ml.

16. Repeat the procedure twice with an interval of 30 seconds between each engagement of the starter.

17. Run command VP037: "Fuel cut stop" ("Stop fuel supply inhibition").

18. Disconnect the diagnostic tool.

19. Disconnect independent starter.

20. Further actions are performed in reverse order.