Engine Oil Pressure Check Procedure

1. Place the vehicle on a two post lift.

2. Disconnect the negative battery terminal.

3. Unscrew the fastening bolts and remove the engine protective tray.

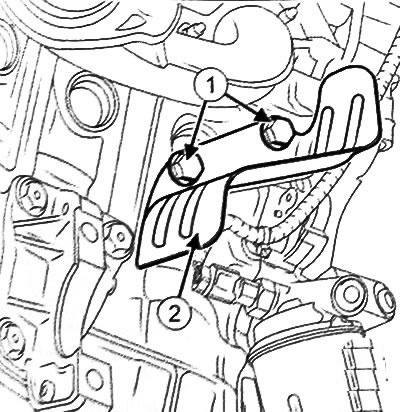

4. Engine D4F: unscrew the bolts (1) and remove the heat shield (2).

5. Remove the oil pressure sensor (see related section below).

6. Check the operation of the oil pressure date with a 2 mm drift and a multimeter.

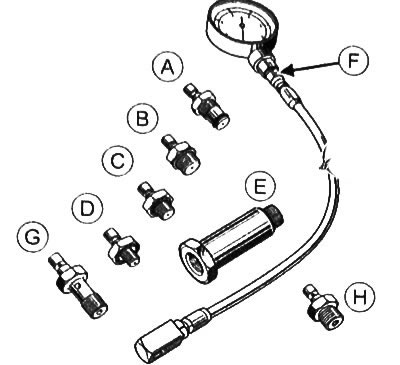

7. Place the oil pressure gauge (Mot. 836-05) with a suitable tip using a 22 mm socket for removing and installing oxygen sensors (Mot. 1495-01) or end cap length (with 12.7 mm square).

D4F engine: C+F tips K4M, K7M and K9K engines: E+C+F tips

8. Start the engine.

9. Monitor the engine oil pressure at idle speed of the engine at operating temperature (80°C or at the first operation of the radiator fan).

10. If the oil pressure is low, make sure that the oil filter is not clogged, and that the engine oil is free of dirt and small chips. Check the condition of the oil pump.

11. Check oil pressure at 3000 rpm.

Note:

D4F engine:

- at idle: 1.5 bar

- at 3000 rpm: not less than 3.9 bar

- maximum oil pressure: 5.3 bar

Engine K7M:

- at idle: 1.3 bar

- at 3000 rpm: more than 3.7 bar

- maximum oil pressure: 5.0 bar

K4M engine:

- at idle: 0.5 bar

- at 4000 rpm: more than 3.1 bar

- maximum oil pressure: 4.4 bar

Engine K9K:

- at idle: 0.8 bar

- at 3000 rpm: more than 3.4 bar

- maximum oil pressure: 5.2 bar

12. Turn off the engine.

13. Remove the oil pressure gauge (Mot. 836-05) with adapters.

14. Further installation is carried out in the reverse order of removal.

15. Remove any spilled oil with a cloth.

16. Wait at least 10 minutes.

17. Check the oil level with the dipstick.

18. If necessary, add oil to the engine.

19. Start the engine and check for leaks from the engine oil pressure switch.