Attention:

- Do not scratch the aluminum contact surfaces, any damage to the contact surfaces may cause leakage.

- Use safety goggles with side protection and sealed gloves (nitrile type).

1. Clean the contact surfaces with a strong cleaner to dissolve any gasket residue. To do this, apply the cleaning agent to the surfaces to be cleaned, wait about ten minutes, and then remove the residue with a wooden or plastic spatula.

Attention:

- Do not allow cleaning agent to come into contact with paint surfaces.

- Thoroughly clean the cylinder head to prevent foreign bodies from entering the oil lines. Failure to do so may result in clogged oil lines, resulting in engine damage.

2. Place the pistons in the mid-stroke position to prevent contact with the valves while tightening the cylinder head bolts.

3. Install the cylinder head with a new gasket.

4. Install new cylinder head bolts.

5. Tighten the cylinder head:

- tighten the cylinder head bolts to an initial torque of 20 Nm,

- make sure that all cylinder head bolts are tightened to the required torque,

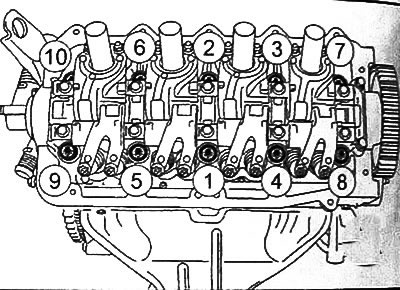

- tighten the cylinder head bolts in the sequence shown by 230°±6°

6. Further installation is carried out in the reverse order of removal.