Examination

1. Disconnect the ground cable from the battery (contact the head Engine electrical equipment for Scenic models).

Attention! If the car radio in your car is coded, make sure you know the code before disconnecting the battery.

2. Apply the handbrake, then jack up the front right corner of the vehicle until the wheel is off the ground. Support the vehicle with an axle support and engage 5th gear. Thus, the engine crankshaft can be easily turned by turning the right wheel. Alternatively, turn the engine crankshaft with a wrench on the crankshaft pulley bolt.

3. Rotate the crankshaft to set the #1 piston to TDC on the compression stroke and insert the dowel pin to check the crankshaft position as described in Chapter Engine repair.

4. Cover the generator with a plastic bag or cloth.

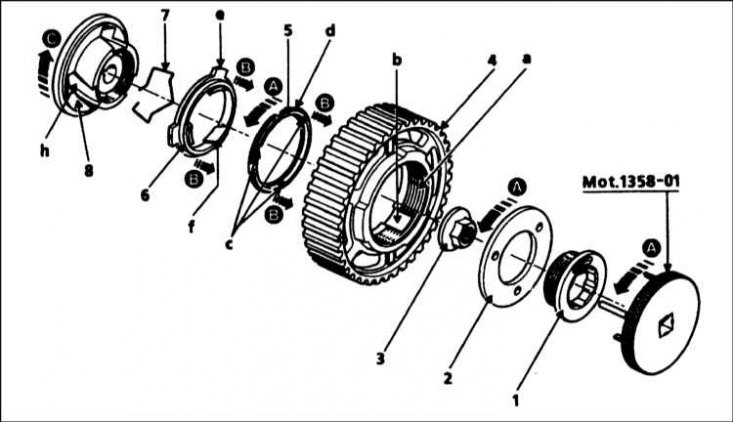

Gear type design "IAA"

1 - Central bolt - left-hand thread; 2 - Pulley plate; 3 - Pulley nut *; 4 - Toothed pulley frame; 5 - Injection timing correction ring; 6 - Angle adjusting ring; 7 - Spring blocking the central bolt; 8 - Pulley hub; A - Anti-clockwise movement causes the instrument to be set; B - Transverse movement of the rings; C - Clockwise rotation, manifested on the pump shaft; a - Thread for "d"; b - Straight notches for rail tabs "e"; c - Grooves for tool pins; d - Thread for "A"; e - Guide ledges; f - Bevelled guides for "h"; h - Beveled guides for "f"

* Non-ferrous metal nut with built-in washer

Models with F8Q engine - Lucas fuel pump

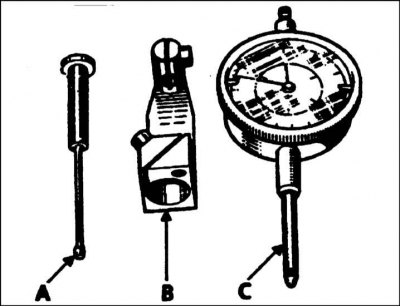

1. Now you need a micrometer with a dial and a special probe (tool Renault Mot. 1079) (refer to accompanying illustration).

2. Remove the level plug from the top of the pump and remove the sealing washer.

3. Insert the probe into the hole so that its tip rests on the rotor mounting lug (refer to illustrations).

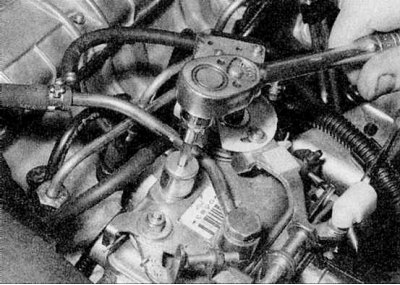

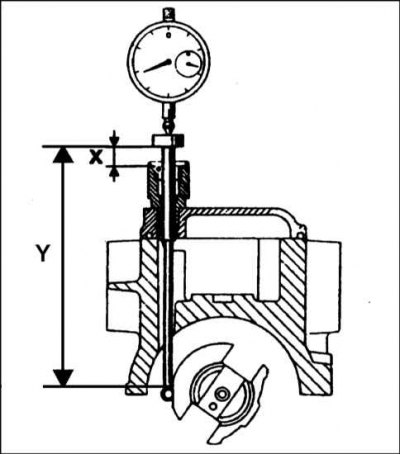

4. Position the dial micrometer on the fuel pump housing. The micrometer should be placed on the probe so that its plunger is located in the middle of the stroke.

5. Remove the dowel pin, then turn the crankshaft about a quarter of a turn counterclockwise and reset the micrometer to zero. Check that the probe is located on the surface of the mounting hole sealing washer.

6. Slowly turn the crankshaft clockwise (returning the engine to TDC), until the locating pin is again.

7. Read the micrometer reading, the result should match the value indicated on the label on the pump cover.

8. If the result obtained does not match the given data, proceed as follows.

9. Turn away and remove a cover of a gear drive belt from a gear wheel of the fuel pump.

10. Remove the probe and block the pump pulley with the Renault Mot. 1200-01 (refer to section Removal and installation of the fuel pump).

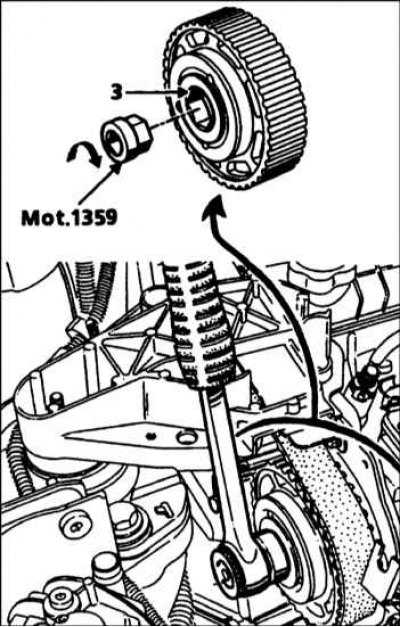

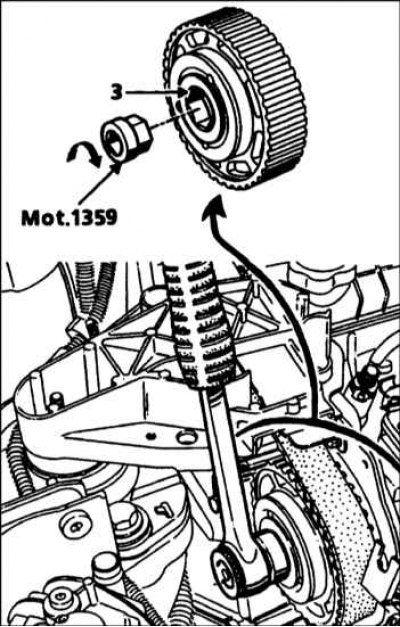

11. Fuel pump pulley type "IAA" (Micrometric Angle Adjustment) consists of a hub/plate and a serrated rim that are bolted together with a central bolt. The plate has three holes for a special tool (Renault Mot. 1358 for pulley "IAA" and toothed drive belt "HTD" or Mot. 1358-01 for timing belt "HTD2"), which is used to rotate the pump shaft. But first, the central bolt is loosened with a Renault Mot tool. 1359 (refer to illustration).

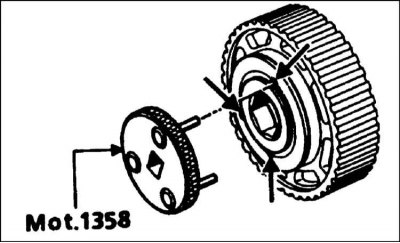

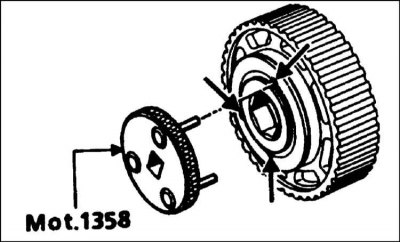

12. Install the special tool in the three holes and rotate the insert so that the three pins of the tool fit into the three slots in the advance ring (refer to accompanying illustration).

13. Now rotate the insert tool assembly clockwise until the tool is locked. This will bring the pulley into position to start the adjustment.

14. Remove the pulley locking tool and turn the crankshaft 2 turns (setting piston number 1 back to TDC) until the tool is inserted again.

15. Now rotate tool Mot. 1358-01 counterclockwise until the correct injection timing is indicated on the micrometer. If the injection torque exceeds the desired value during installation, turn the tool back 0.7 mm below the value before re-adjusting.

16. Remove the special tool, then tighten the center bolt (left hand thread) tightening torque 20 Nm using tool Mot. 1359.

17. Remove the dowel pin.

18. Install tool Mot. 1200-02 to block the pulley. Turn the crankshaft counterclockwise by hand until the locking tool contacts the pulley.

19. Tighten the central bolt to 90 Nm using tool Mot. 1359.

20. Remove the pulley locking tool, turn the crankshaft 2 turns and recheck the injection timing of the pump.

Attention! If it is not possible to set the correct injection timing, check the adjustment of the camshaft and fuel pump gears (refer to illustration "Injection pump gear position"). The location is considered correct if all the alignment marks are well aligned and if there are exactly 30 teeth from the mark on the camshaft gear to the mark on the fuel pump gear.

21. Having correctly set the injection moment, remove the micrometer. Remove the probe from the hole and install the plug with the sealing washer.

22. Connect the fuel injector lines to the pump, securely tightening the union nuts.

23. Remove the plastic bag covering the generator.

24. Lower the vehicle to the ground and connect the earth cable to the battery.

25. Fill and bleed the fuel system (refer to section Filling and bleeding the fuel system).

26. Check and, if necessary, adjust the idle speed and deceleration speed as described in Section Checking and adjusting idle speed and deceleration speed.

F8Q 620 engine - Bosch pump

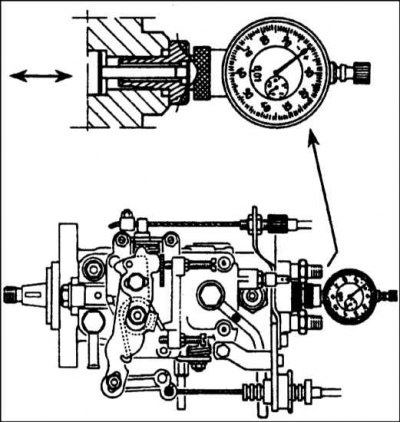

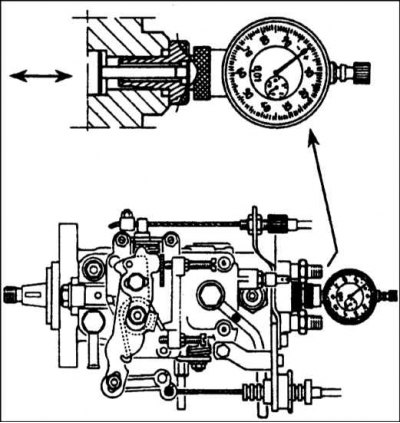

1. You will need a micrometer with a dial, a special probe and a nozzle that are screwed into the hole at the end of the pump (tool Renault Mot. 856) (refer to accompanying illustration).

2. Remove the union nuts securing the injector tubes to the high pressure fuel pump. Close open couplings to prevent dirt from entering.

3. Turn away a plug from the left side of the fuel pump, between connections of tubes of atomizers.

4. Insert the probe and connect it to the micrometer placed directly in front of the hole.

5. Remove the dowel pin and turn the crankshaft about a quarter of a turn counterclockwise, then reset the micrometer to zero. To do this, apply the handbrake, then jack up the front right corner of the car until the wheel is off the ground. Support the vehicle with an axle support and engage 5th gear. Thus, the engine crankshaft can be easily turned by turning the right wheel. Alternatively, turn the engine crankshaft with a wrench on the crankshaft pulley bolt.

6. Slowly turn the crankshaft clockwise (setting the engine back to TDC), until the dowel pin can be inserted again.

7. Read the micrometer reading; the result obtained must correspond to the data given in Specifications. Please note that the injection point is also marked on the pump gas lever.

8. If the result obtained does not match the given data, proceed as follows:

9. Loosen the three bolts of the right pump support and the nuts of the left pump support, then slowly rotate the pump housing until you find the position where the micrometer reads the value indicated in Specifications meaning. Then tighten the fixing nuts and bolts, making sure that the readings on the micrometer have not changed.

10. Remove the dowel pin and rotate the crankshaft one and three quarter turns clockwise. Make sure the micrometer reads zero.

11. Slowly turn the crankshaft clockwise (setting piston #1 to TDC), until the dowel pin can be inserted again. Recheck the value of injection timing.

12. If adjustment is necessary, loosen the pump mounting nuts and bolts and repeat the steps in the paragraphs above.

13. Having correctly set the injection moment, remove the micrometer, probe and install the plug, clamping it with the Specifications effort. Tighten the three bolts of the right pump support and the nuts of the left pump support as shown in Specifications effort.

14. Connect the fuel injector tubes to the pump and securely tighten the union nuts.

15. Remove the plastic bag from the generator.

16. Remove the dowel pin.

17. Lower the car to the earth and attach a cable of weight to the battery.

18. Fill and prime the fuel system as described in Section Filling and bleeding the fuel system.

19. Check and, if necessary, adjust the idle speed and deceleration speed as described in Section Checking and adjusting idle speed and deceleration speed.

F9Q engines - Bosch pump

Note. To adjust the injection timing on these engines, many special Renault tools are required. Therefore, if there are no tools, contact a Renault workshop to adjust the injection timing.

1. You will need a micrometer, a special probe and a nozzle that are screwed into the hole at the end of the pump (tool Renault Mot. 856) (refer to illustration).

2. Remove the crankcase ventilation oil separator.

3. Remove the union nuts securing the injector tubes to the high pressure fuel pump. Close open couplings to prevent dirt from entering.

4. Turn away a plug from the left side of the fuel pump, between connections of tubes of atomizers.

5. Insert the probe and connect it to the micrometer placed directly in front of the hole.

6. Remove the dowel pin and turn the crankshaft about a quarter of a turn counterclockwise, then reset the micrometer to zero. To do this, apply the handbrake, then jack up the front right corner of the car until the wheel is off the ground. Support the vehicle with axle stands and engage 5th gear. Thus, the engine crankshaft can be easily turned by turning the right wheel. Alternatively, turn the engine crankshaft with a wrench on the crankshaft pulley bolt.

7. Slowly turn the crankshaft clockwise (setting the engine back to TDC), until the dowel pin can be inserted again.

8. Read the micrometer reading; the result obtained must correspond to the data given in Specifications. Note that the injection timing is also marked on the pump throttle lever.

9. If the result obtained does not match the given data, proceed as follows:

10. Disconnect the ground cable from the battery (contact the head Engine electrical equipment for Scenic models), disconnect the electrical wiring connector of the electronic control module, then unscrew and remove the module from the bracket.

11. Disconnect the two fuel hoses from the top of the fuel filter.

12. Disconnect the pump harness at the main connector attached to the ECM bracket. Release the electrical wiring from the mounting brackets and move it to the side.

13. Disconnect the wiring connector from the fuel heater on the filter.

14. Turn away and remove assemblage of the fuel filter and an arm of the electronic control module.

15. Turn away and remove a cover of a cogwheel of the fuel pump.

16. Install the tool holding the fuel pump gear (Renault Mot. 1200) (refer to section Removal and installation of the fuel pump).

17. Fuel pump pulley type "IAA" (Micrometric Angle Adjustment) consists of a hub/plate and a serrated rim that are bolted together with a central bolt (left hand thread) (refer to illustration "Gear type design "IAA"). The plate has three holes for a special tool (Renault Mot. 1358-01), which is used to rotate the pump shaft. But first, the central bolt is loosened with a Renault Mot tool. 1359 (refer to illustration).

18a. Install the special tool in the three holes and rotate the insert so that the three pins of the tool fit into the three slots in the advance ring (refer to illustration).

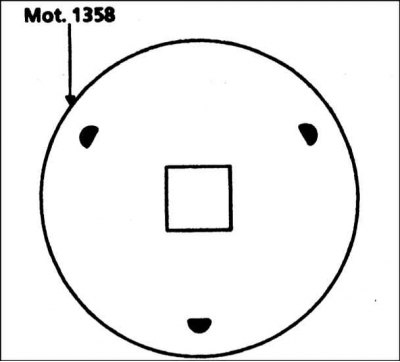

18b. Note that in the absence of the tool Mot. 1358-01 tool Mot. 1358 can be converted by grinding three 1.5 mm pins (refer to accompanying illustration).

19. Now rotate the tool/insert assembly clockwise until the tool is locked. This will bring the pulley into position to start the adjustment.

20. Remove the pulley locking tool and turn the crankshaft 2 turns (setting piston number 1 back to TDC) until the tool is inserted again.

21. Now rotate tool Mot. 1358-01 counterclockwise until the correct injection timing is obtained on the micrometer. If the injection torque exceeds the desired value during installation, turn the tool back 0.7 mm below the value before re-adjusting.

22. Remove the special tool, then tighten the center bolt (left hand thread) tightening torque 20 Nm using tool Mot. 1359.

23. Remove the dowel pin.

24. Install tool Mot. 1200-02 to block the pulley. Turn the crankshaft counterclockwise by hand until the locking tool contacts the pulley.

25. Tighten the central bolt to 90 Nm using tool Mot. 1359.

26. Remove the pulley blocking tool, turn the crankshaft 2 turns and recheck the injection timing of the pump.

Attention! If it is not possible to set the correct injection timing, check the adjustment of the camshaft and fuel pump gears (refer to illustration "Injection pump gear position"). The location is considered correct if all the alignment marks are well aligned and if there are exactly 30 teeth from the mark on the camshaft gear to the mark on the fuel pump gear.

27. Having correctly set the injection moment, remove the micrometer. Remove the probe from the hole and install the plug with the sealing washer.

28. Install and connect the fuel injector lines and tighten the couplers.

29. Install the crankcase ventilation oil separator.

30. Establish a cover of a gear drive belt on a gear wheel of the fuel pump.

31. Install the fuel filter and ECM bracket.

32. Connect the supply and return fuel pipes and hoses and the electrical wiring of the fuel filter heating system.

33. Install the electronic control module and connect all electrical wiring to the pump.

34. Lower the car to the ground and attach the mass cable to the battery.

35. Fill and bleed the fuel system as described in Section Filling and bleeding the fuel system.