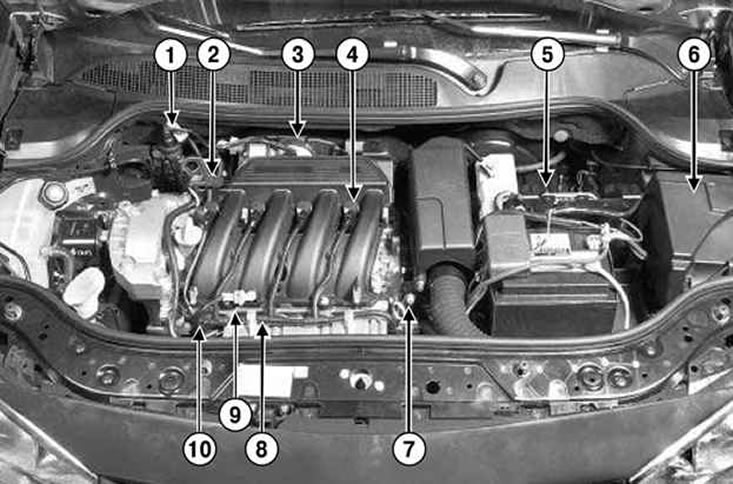

Pic. 2.225. The location of the elements of the injection system in the engine compartment of a Megane II car with a K4J engine: 1 - solenoid valve for fuel vapor recirculation; 2 - absolute pressure sensor; 3 - throttle valve block with a servo drive; 4 - ignition coil; 5 - ECU of the injection system; 6 - block of protection and switching; 7 - coolant temperature sensor; 8 - knock sensor; 9 – air temperature sensor; 10 - fuel distribution rail and nozzles

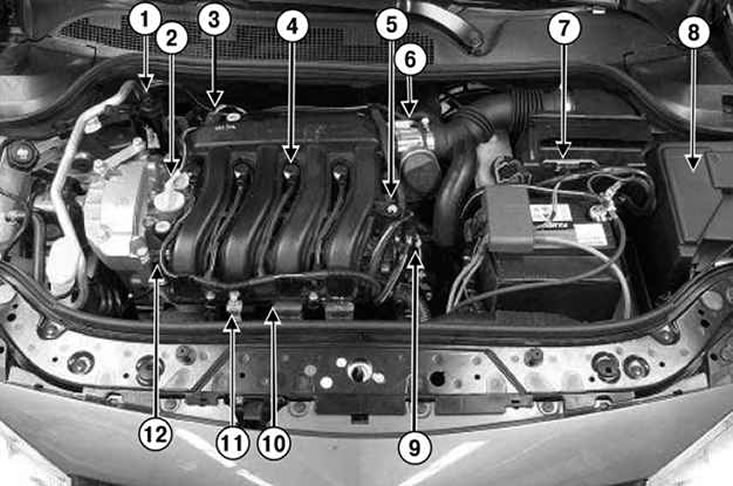

Pic. 2.226. The location of the elements of the injection system in the engine compartment of a Megane II car with a K4M engine: 1 - solenoid valve for fuel vapor recirculation; 2 - solenoid valve of the camshaft phase regulator; 3 - absolute pressure sensor; 4 - ignition coil; 5 - camshaft position sensor; 6 - throttle valve block with a servo drive; 7 - ECU of the injection system; 8 - block of protection and switching; 9 - coolant temperature sensor; 10 - knock sensor; 11 - air temperature sensor; 12 - fuel distribution rail and nozzles

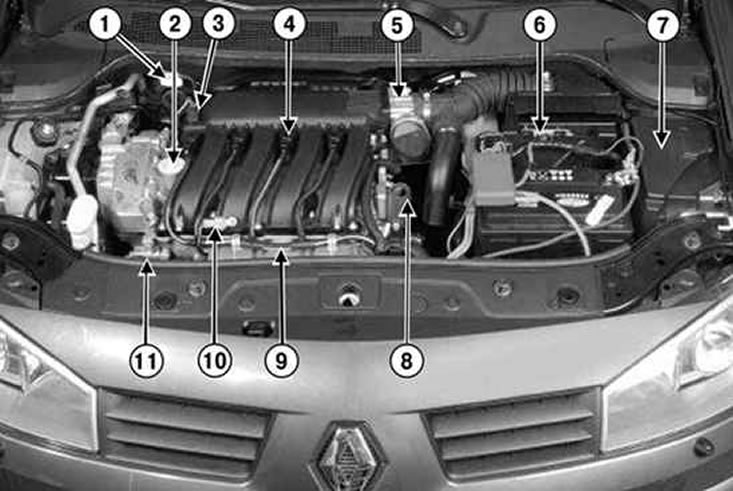

Pic. 2.227. The location of the elements of the injection system in the engine compartment of a Megane II car with an F4R engine: 1 - solenoid valve for fuel vapor recirculation; 2 - solenoid valve of the camshaft phase regulator; 3 - absolute pressure sensor; 4 - ignition coil; 5 - throttle valve block with a servo drive; 6 - ECU of the injection system; 7 - block of protection and switching; 8 - coolant temperature sensor; 9 - knock sensor; 10 – air temperature sensor; 11 - fuel distribution rail and nozzles

ECU with 128 pins

SAGEM brand S3000 manages injection and ignition systems and has multipoint sequential injection (engines F4R, K4J).

There is no TDC sensor on the camshaft of the piston of the first cylinder, therefore, the synchronization of the control of the system elements with the engine working process is carried out according to the program using the signals of the TDC sensor. The engine is started in semi-sequential mode (to synchronize the control of system elements with the working process of the engine), then enters the serial synchronized mode.

K4M engines are equipped with a TDC sensor for the first cylinder on the camshaft. Synchronization of the control of system elements with the working process of the engine (determination of the TDC of the piston of the 1st cylinder) carried out by this sensor. The engine starts in semi-sequential mode (to synchronize the control of system elements with the working process of the engine), then enters the serial synchronized mode.

The injection system malfunction warning light on the instrument panel is active.

Application of a special signal lamp for a malfunction of the injection system (OBD warning light «On-Board Diagnostic System»). Its presence is due to the installation «on-board diagnostic system».

Special precautions due to the presence of an electronic anti-theft immobilizer system.

Due to the installation of a third-generation electronic anti-theft engine start blocking system, the ECU is replaced using a special technique.

Fuel supply system without fuel return to the fuel tank.

The pressure regulator is located in the node «fuel pump - fuel level sensor».

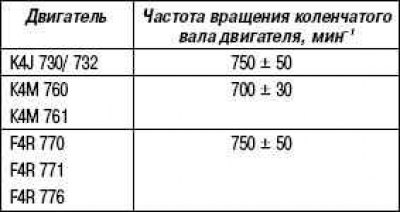

Idle mode (hot engine).

Rated idle frequency

The idle speed is adjusted depending on:

- coolant temperature;

- battery voltage;

- air conditioner status (on/off);

- oil pressure (car with K4M engine);

- selector lever position (car with F4R engine).

Maximum crankshaft speed

Protection when exceeding the maximum permissible speed of the crankshaft of a cold engine K4J

If the coolant temperature is below 60°C, or within 10 seconds after starting the engine, the fuel supply is cut off at 5800 min–1.

K4M

If the coolant temperature is below 75°C, or within 10 seconds after starting the engine, the fuel supply is cut off at 5800 min–1.

F4R

If the coolant temperature is below 75°C, or within no more than 17 seconds after starting the engine, the fuel supply is cut off at 5900 min–1.

Protection when exceeding the maximum permissible speed of the crankshaft of a hot engine

If the engine is hot, this value returns to its normal value.

K4J and K4M

Fuel supply stops at 6500 min–1 regardless of the gear (manual or automatic transmission).

F4R

Fuel supply stops at 6000 min–1 regardless of the gear (Manual Transmission) and 6300 min–1 (Automatic transmission).

Camshaft Phase Control

K4M

The valve timing smoothly changes from 0 to 43°according to the angle of rotation of the crankshaft. The phase regulator is controlled by a solenoid valve, which is energized in the form of a variable signal of the degree of cyclic opening from the injection computer.

F4R

The phase regulator is a solenoid valve that is powered according to the principle «Not really» from the injection computer.

Control of the electric fan of the engine cooling system and signal lamp of the emergency coolant temperature

The request comes from the injection computer via the multiplex network (centralized coolant temperature control function). The supply voltage is supplied to the electric fan from the protection and switching unit.

Air conditioning compressor control

The request comes from the injection computer via the multiplex network. The request is generated on the basis of data on the operation of the air conditioning system, as well as taking into account the temperature of the coolant. The air conditioning compressor is powered through the protection and switching unit.

Fuel pump control

The request comes from the injection computer. The supply voltage is supplied to the fuel pump from the protection and switching unit.

Regulator - limiter

The speed limiter and the air conditioning system are configured automatically.

Oxygen sensor

Two oxygen sensors are used, installed at the inlet and outlet of the catalytic converter.

Throttle block

Air supply and idle speed are controlled by a servo throttle body.

Protection and switching unit

The unit supplies power to the following units:

- ignition coils;

- fuel pump;

- air conditioning compressor;

- electric fan;

- some injection system actuators (nozzles, canister purge solenoid valve, etc.).

The protection and switching unit is located in the engine compartment next to the battery. The unit provides protection for the circuits of some electrical appliances.

To perform this function, the unit includes fuses and several built-in relays:

- relay ««+» after the ignition switch»;

- fuel pump relay;

- air conditioner compressor relay;

- relay of the electric fan of the engine cooling system;

- starter relay (starter relay control).

These relays are non-removable.

injection computer

The unit constantly receives information about the electrical power generated by the generator via the multiplex network. This is necessary so that the power consumption of the car does not exceed the capacity of the generator. The main task is to ensure the charging of the battery.

Accelerator pedal

Replacing the accelerator pedal is not difficult.

The ECU takes the value read when the ignition is switched on as the pedal released reference value.

The sensor, made in the form of a two-track potentiometer, provides information to the computer about the position of the accelerator pedal. The signal voltage from the sensor has two conductive paths with different resistance. Voltage is applied from the first conductive track (0-5V), twice the signal voltage from the second track (0-2.5V). Comparing the voltage of both signals makes it possible to verify that the generated signal corresponds to the current value.

Idle mode

Idling speed increases by no more than 160 min–1, if the battery voltage is below 12.7V.

In the event of a present and stored MAP sensor fault, the idle speed setpoint is set to:

- 896 min–1 (engines K4J and K4M),

- 1024 min–1 (F4R engine).

The S3000 injection system controls the activation of three warning lights and the display of messages according to the severity of the detected faults in order to determine the necessary diagnosis.

The injection ECU controls the warning lights and messages on the instrument panel. These warning lights come on during the starting phase of the engine, and also when there is a malfunction in the injection system or the engine overheats.

Commands to turn on signal lamps are transmitted to the instrument panel via the multiplex network.

The principle of operation of signal lamps

When starting the engine by pressing the start button «start»

signal lamp «on-board diagnostic system» lights up for about 3 seconds and then goes out.

In the event of a malfunction in the injection system (1st degree of severity)

Written message is displayed «injection a controle» (check injection system), accompanied by the turning on of the signal lamp «service». This indicates a decrease in the level of safety and the need to use the engine in «sparing» mode. The owner must rectify the fault as soon as possible.

These faults may be caused by:

- malfunction of the throttle valve with a servo;

- malfunction of the accelerator pedal position sensor;

- absolute pressure sensor malfunction;

- ECU malfunction;

- malfunctions in the power supply circuits of actuators;

- malfunctions in the power supply circuit of the computer.

In the event of a serious malfunction of the injection system (2nd degree of severity)

The red engine symbol and the message are displayed «stop» (only on matrix display), and a written message appears «mjection defaillante» (injection system is faulty), accompanied by the warning light «stop» and sound signal.

When the engine overheats

Engine temperature alarm symbol appears (only on matrix display) with written communication «surchauffe moteur» (engine overheating), accompanied by the warning light «stop» and sound signal. In this case, stop driving immediately.

If a malfunction is detected that leads to an excess of exhaust gas toxicity standards

The signal lamp turns on «on-board diagnostic system» with engine symbol:

- «flashing light» in case of a malfunction that can lead to the destruction of the catalytic converter (misfires of the mixture leading to its destruction). In this case, stop driving immediately.

- «constant light» in case of exceeding the norms of toxicity of exhaust gases (mixture misfiring resulting in increased toxicity, catalytic converter malfunction, oxygen sensor malfunction, mismatch between oxygen sensor signals, and adsorber malfunction).

Communication between the injection computer and the air conditioner computer

The air conditioner is controlled by several ECUs.

The functions of the injection computer include:

- cooling capacity control based on requests from the passenger compartment and the pressure value in the circuit;

- determination of the power consumed by the air conditioner compressor based on the value of the pressure in the circuit;

- issuance of permits to control the electric fan of the engine cooling system, depending on the speed of the vehicle and the pressure in the circuit;

- issuance of permission and prohibition to turn on the compressor.

When the air conditioner is turned on, the air conditioner control panel requests permission to turn on the air conditioner compressor.

The injection computer allows or does not allow:

- the operation of the air conditioning compressor;

- operation of the electric fan of the engine cooling system;

- engine idling.

Control commands to turn on the engine cooling fan and compressor come from the injection computer via the multiplex network. Commands are generated based on information about the operation of the air conditioning system, as well as taking into account the temperature of the coolant and the speed of the vehicle.

The supply voltage is supplied to the electric fan and compressor from the protection and switching unit.

The information used by the air conditioner control unit is transmitted via the multiplex network:

- pin 4 AA - multiplex network line «CAN HIGH»;

- pin 3 AA - multiplex network line «CAN LOW».

The injection computer receives information from the refrigerant pressure sensor through the contacts:

- in J3 refrigerant pressure sensor signal;

- in J2 «+» power supply 5 V refrigerant pressure sensor;

- in K2 «weight» refrigerant pressure sensor.

Algorithm for turning on the air conditioning compressor

During certain periods of operation, the injection computer inhibits the operation of the air conditioning compressor.

Algorithm for maintaining the dynamic characteristics of the engine when starting on a hill.

To facilitate starting the car on a hill, the operation of the air conditioning compressor is prohibited for 20 seconds.

Algorithm for protection against exceeding the maximum permissible engine speed.

The air conditioning compressor stops in the following cases:

- instantaneous engine speed exceeds 6300 min–1;

- constant crankshaft speed exceeds 5760 min–1 for more than 10 s.

Overheat protection algorithm.

The compressor does not work if the coolant temperature is above 115°C at high engine speed and high engine load.

Activation conditions: at engine speeds above 4512 min–1 and intake manifold pressure below 700 Mbar.

Shutdown conditions: After a time delay of 10 seconds has elapsed, the centralized coolant temperature control function is implemented.

The principle of operation of the throttle valve

The throttle valve control idle speed and change the amount of air entering the engine. The unit consists of an electric motor and a potentiometric throttle position sensor with two conductive tracks.

At idle, the throttle position is set depending on the set idle speed, which depends on the number of powerful power consumers turned on (air conditioner) and engine operating conditions (air and coolant temperature).

When you press the accelerator pedal, the throttle valve opens to the appropriate angle.

However, in order to improve driving comfort, the throttle opening is not directly proportional to the driver's control input.

To eliminate jerking, facilitate shifting and ensure safety, the throttle valve allows you to change the engine torque.

Throttle valve standby modes

There are four standby throttle body modes.

1. The mode of limiting dynamic indicators.

This mode is used for malfunctions in electrical circuits for which there is a safe solution suitable for the injection system (malfunction of one of the two conductive paths of the accelerator pedal position sensor or throttle body). This mode limits acceleration performance and maximum throttle opening (the maximum speed is 90 km/h for vehicles with manual transmission and 100 km/h for vehicles with automatic transmission.

2. Mode of loss of control actions of the driver.

This mode is also called «standby electrical position. This mode is used when there is no information about the position of the accelerator pedal, but the injection ECU continues to control the air filling of the engine cylinders (throttle actuator remains controlled). In this mode, the injection ECU sets the accelerator pedal positions for each gear and sets the engine to idle when the brake pedal is pressed. In this case, the maximum speed of the crankshaft in the neutral position of the gearbox is limited to 2500 min–1.

3. Standby mechanical position mode.

This mode is used for malfunctions that lead to loss of throttle control (damper actuator does not work). In this case, the throttle valve is in the mechanical rest position, the injection computer limits the engine speed by stopping injection and the torque by deactivating the cylinders (stop ignition and injection) depending on the position of the accelerator pedal. As a result, the maximum frequency of the crankshaft in full load mode or in the neutral position of the gearbox remains equal to 2500 min–1.

4. Pedal tracking mode.

In case of loss of information about the pressure in the intake manifold, the degree of opening of the throttle valve is directly proportional to the position of the accelerator pedal.

Note. When switching to any of these modes, the signal lamp for a malfunction of the injection system lights up on the instrument panel.

Idle speed correction depending on the coolant temperature (F4R engine)

* Except when the engine is started at a temperature of 15–30°С.

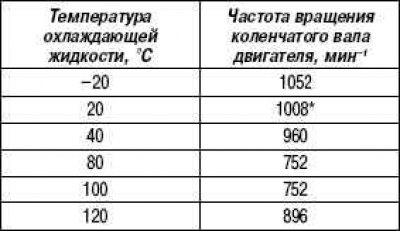

Idle speed correction depending on the coolant temperature (K4J engine)

* Except when the engine is started at a temperature of 15–30°С.

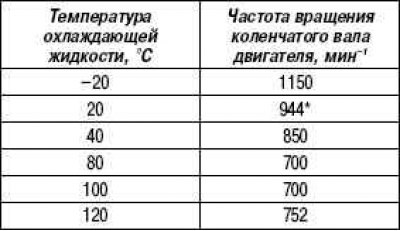

Idle speed correction depending on the coolant temperature (K4M engine)

* Except when the engine is started at a temperature of 15–30°С.

Idle speed correction depending on battery voltage and electrical energy balance

The engine idle speed correction compensates for the voltage drop when the consumer of electricity is turned on, if the battery is weakly charged. The correction starts when the voltage becomes less than 12.7 V. As a result of the correction, the engine speed can be increased by no more than 160 min–1, i.e. up to 910 min–1.

Correction of frequency of rotation of idling at malfunction of the gauge of absolute pressure

If the absolute pressure sensor malfunctions, the idle speed increases to 1024 min–1.

If the engine is started at a coolant temperature of 15–30°C and then remains at idle, a gradual decrease in the crankshaft speed is possible. This is due to the presence of a function to reduce the toxicity of exhaust gases when starting the engine (inclusion of elements of heating of oxygen sensors).