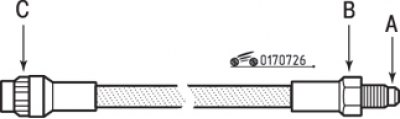

Pic. 7.25. Brake hose: A - the conical surface of the tip; B - tip nut; C - slotted part

Hoses without copper sealing washers are installed on the car. Tightness is achieved by contact of conical surfaces A (pic. 7.25) hose tip. When replacing or disconnecting a hose (pipeline) take care to reduce the leakage of brake fluid. To do this, place a rag under the work area. Seal the expansion tank by placing a plastic circle of equal diameter under its cover, or install a clamp on the tank hose. When disconnecting the hose, plug the holes with pre-prepared plugs. You can also pinch the detachable hose to isolate part of the brake circuit.

For safety reasons, to avoid twisting of the brake hoses, the possibility of their contact with suspension parts, the following work order must be observed.

Withdrawal procedure:

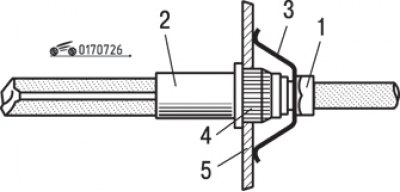

Pic. 7.26. Connecting the brake hose to the pipeline: 1 - union nut of the pipeline; 2 - hose; 3 - spring retainer; 4 - slotted part of the hose tip; 5 - connection bracket

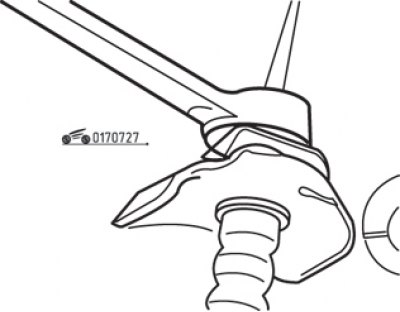

Pic. 7.27. Unscrewing with a ring wrench with a slot of the nut connecting the hose to the pipeline

- loosen the union nut (pic. 7.26) with slotted spanner (pic. 7.27) just enough to release the spring clip;

- remove the splined part of the hose tip from the splined hole of the bracket;

- if necessary, unscrew the hose from the front brake caliper.

Installation order:

- set the steering wheel to the position of the rectilinear movement of the car;

- lift the front wheel off the ground on the desired side;

- screw the hose into the hole in the brake caliper and tighten the tip to the specified torque;

- fasten the splined end of the hose to the bracket (see fig. 7.26), without twisting the hose, and make sure that the tip fits freely into the slotted hole of the bracket;

- install the spring clip;

- connect the tubing to the hose, making sure that the hose is not twisted while screwing on the union nut. Tighten the union nut to the specified torque;

- bleed the air from the hydraulic brake system.