Assembly

Assembly order:

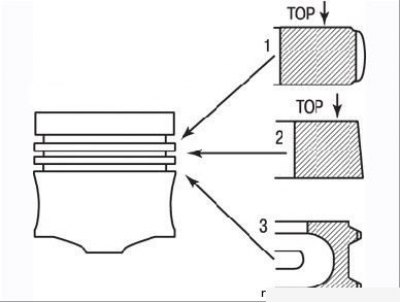

Figure 3.58. Piston ring profiles

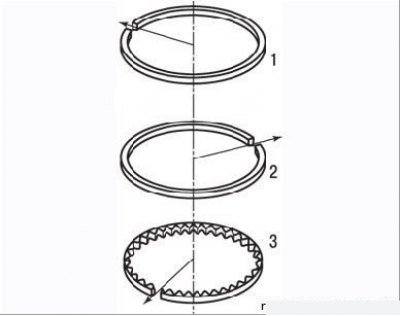

Figure 3.59. The location of the locks of the piston rings at an angle of 120°relative to each other

- install rings on the pistons - put them on through the piston crown, starting with the oil scraper ring and using the same flat feeler gauges that were used when removing the rings. Piston ring profiles are shown in Figure 3.58. Compression rings are installed with the inscription «TOR» up. They are very fragile, so be careful when installing. Spread the piston ring locks at an angle of 120°relative to each other (Figure 3.59);

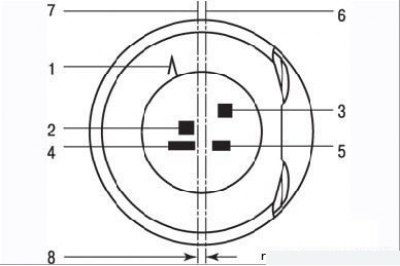

Figure 3.60. Piston marking: 1 - the direction of installation of the piston label «L» towards the flywheel 2, 4, 5 - supplier's marking; 3 - piston size group (A–B–C); 6 - axis of symmetry of the piston; 7 - the axis of the hole for the piston pin; 8 - axis offset (7) holes for the piston pin relative to the plane of symmetry (6) piston is 0.9mm

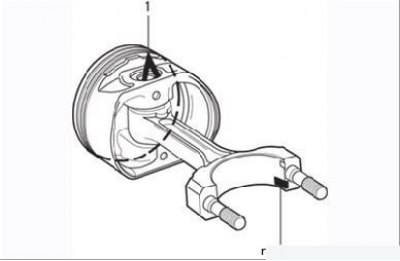

Figure 3.61. The position of the connecting rod relative to the piston: label «L» (1) on the piston crown must be at the top, and the locking lug of the bearing shell (2) bottom end of the connecting rod - below

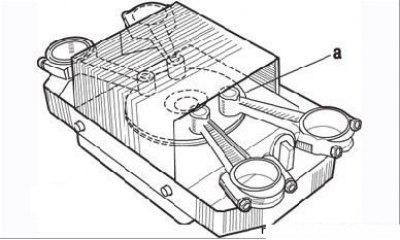

Figure 3.62. Heating on the electric stove of the upper heads of the connecting rods: a - a piece of tin solder

- assemble the piston with the connecting rod. Label «L» on the bottom of the piston (Figure 3.60) should point toward the flywheel and the connecting rod bearing shell retainer tab should be as shown in Figure 3.61. Place the upper connecting rod heads on a 1500 W hotplate as shown in Figure 3.62. To control the heating temperature of the connecting rods, place a small piece of tin solder with a melting point of approximately 250°C on the top head of each connecting rod in area a;

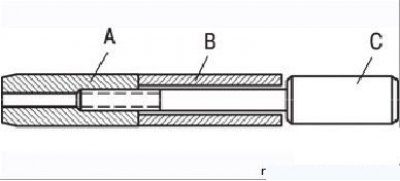

Figure 3.63. Piston pin installation (IN) on the mounting rod (WITH) and connection with centering device (A)

- prepare the piston pins. Make sure they fit freely into their respective pistons. Install the piston pin on the locating rod, screw in the centering tool until it stops and then unscrew it 1/4 turn (Figure 3.63);

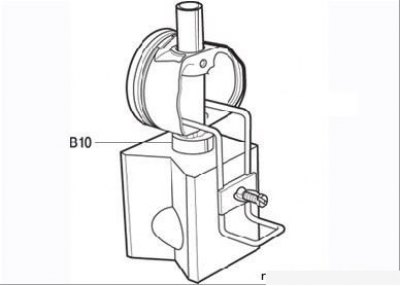

Figure 3.64. Fitting the piston to the connecting rod assembly tool: B10 - sleeve-limiter

- place the piston on the stand, orienting it as shown in Figure 3.61. Between the piston and the stand, place a sleeve that limits the movement of the centering device when pressing the piston pin (Figure 3.64);

- lubricate the centering device and piston pin with engine oil;

Attention! Subsequent operations must be carried out as quickly as possible to avoid cooling the connecting rod.

- when the solder temperature reaches the melting point (solder will turn into a drop), wipe off a drop of solder;

- insert the connecting rod into the piston;

- as quickly as possible, insert the piston pin until the stop of the centering device into the stand;

- remove the centering device from the pin;

- make sure that the piston pin at any position of the connecting rod does not go beyond the boundaries of the piston bosses.